Within many industrial processes, plants, equipment and workers may be subject to the risk of the formation of explosive atmospheres. The explosive risk can occur when agents such as combustibles or flammables come into contact with a comburent (the oxygen inside the air) and with an ignition factor which in turn can be determined by electrical factors (electrostatic discharges or sparks) or thermal factors (very high temperatures).

Operators in these sectors are obliged to take all preventive measures necessary to minimize the occurrence of the explosive risk. To this end, it was deemed necessary to intervene also at a regulatory level with the European Union Directive which introduced the ATEX 2014/34 / EU certification aimed at harmonizing the rules for the use of equipment and systems used in potentially explosive atmospheres. .

In-depth study of the ATEX regulation

With the term ATEX (acronym for Atmosphères Explosibles) the European Union wanted to include the regulatory instruments governing the environment where there is a potential risk of explosion, called the ATEX environment. The ATEX Directive is therefore applicable to all systems and products that will be used within these potentially explosive environments including the types of pneumatic double diaphragm pumps. The assessment of explosive risks to which the ATEX directive applies is based on the determination of the extension of the hazardous areas within which there is a potential risk of explosion. Specifically, the directive refers to the products applicable in two macro-groups:

- Group 1: includes appliances intended to be used underground and on the surface in the mining sector where it may be possible to release firedamp and other combustible dusts.

- Group 2: includes appliances intended for use in other environments in which the possibility of an explosive atmosphere is likely to occur.

The products belonging to Group 2 are in turn divided into three categories according to the degree of risk of the explosive episode.

- CATEGORY 1 (zone 0): flammable material continuously present or present for long periods.

- CATEGORY 2 (zone 1): materiale infiammabile presente occasionalmente durante il normale funzionamento.

- CATEGORY 3 (zone 2): flammable material present in abnormal conditions for short periods

Directive 99/92 / EC, aimed at regulating the protection of the health of workers exposed to the risk of explosive atmospheres, divides the risk areas into two categories:

- AREA G: where the explosive atmosphere can be caused by a mixture of air and flammable substances in the form of gas, vapor and fog. Within this area, the risk areas are as follows:

- Zone 0 (or 0G): area in which the explosive atmosphere is present permanently or for long periods.

- Zone 1 (or 1G): area in which the explosive atmosphere is present during normal activities.

- Zone 2 (or 2G): area in which the explosive atmosphere is not likely to occur during normal activities.

- AREA D: where the explosive atmosphere can form in the form of a cloud of combustible dust in the air. Within this area, the risk areas are as follows:

- Zone 20 (or 0D): corresponds to an area in which an explosive atmosphere is present permanently or for long periods or often.

- Zone 21 (or 1D): describes an area in which occasionally during normal activities the formation of an explosive atmosphere is likely.

- Zone 22 (or 2D): describes the area in which the formation of an explosive atmosphere is not likely during normal activities.

The application sectors of pumps built according to ATEX standards

The ATEX legislation is applied within all industrial processes that involve chemical or physical reactions involving the contact of flammable or combustible agents with oxidizing elements. We list some risk application cases within the target sectors of Debem’s double diaphragm pneumatic pumps.

- Chemical sector: within the production processes of the chemical industry there is the possibility of creating explosive atmospheres during the transformation phases of chemical agents where solvents, hydrogen, mists, dusts and other vapors known as flammable often come into play or unstable.

- Petrochemical Industry: the risk of explosion is very high due to the use of flammable liquids during oil refining or gas production processes. The oil and gas transformed during the manufacturing processes are by their nature combustible and therefore capable of developing a high explosive risk.

- Paper, Wood and Packaging Industry: explosive situations may occur due to the use of highly flammable materials such as paper, wood, wood flour and cork. In woodworking operations, wood powders are produced which can form explosive mixtures when they encounter oxygen.

- Painting systems: the risk of creating an explosive atmosphere exists both in spray painting systems due to the presence of flammable liquids, and in powder painting systems due to the presence of organic elements in the resin of the paint powder.

- Energy sector: the production of energy requires a process of combustion of fossil elements such as coal, oil and natural gas. Possible contact with oxygen present in the air can constitute an explosive risk.

- Biogas plants: inside the fermentation and biogas production plants there is a constant presence of an explosive atmosphere localized in the storage tanks and fermenters that contain the organic materials.

- Agri-food sector: the handling of materials stored inside silos causes the consequent emission into the environment of dust which, remaining suspended in the air, constitutes a high explosive risk.

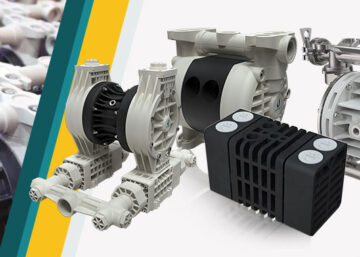

ATEX certified DEBEM pneumatic pumps

The high presence of ATEX risk sectors entails a timely response from application manufacturers to the various requirements imposed on the choice of materials, even in the context of the construction of double diaphragm pumps. To allow a reliable use of the diaphragm pump, it is necessary to use electrically conductive or static dissipative materials. In terms of materials, DEBEM pneumatic pumps are made of conductive plastics containing carbon fiber. This construction feature makes the pumps safer in the event of electrostatic charges than other pumps on the market made with carbon powders which are characterized by greater cost-effectiveness of materials, but with a very low level of electrical conductivity.

All the pneumatic pumps of the Cubic and Boxer line by Debem meet the requirements of the legislation and are equipped with ATEX certification. Cubic and Boxer pumps are produced in explosion-proof execution in accordance with the Directive and according to harmonized European standards. The Cubic and Boxer line pumps are made in ATEX execution for use in Zone 2 – Zone 22 (Series II 3 / 3GD C IIB T4) corresponding to areas with the presence of flammable gas and dust. Upon specific request when ordering, the pumps can be made in the CONDUCT version for use in Zone 1 – Zone 21. (Series II 2 / 2gd IIB T4).

Debem can provide prompt support to all production needs in the ATEX field right from the analysis and design phase. Debem double diaphragm pumps comply with all the standards required by the legislation and constitute a safe and reliable device for the environment at risk of explosions and for the workers associated with it. Contact the Debem sales team for more information.