Production and storage of biodiesel

Biodiesel is the only source of renewable energy in liquid form currently available on the market. Safe to store and handle, biodiesel is biodegradable, non-toxic and it’s the first and only alternative fuels, recognised by the United States Environmental Protection Agency.

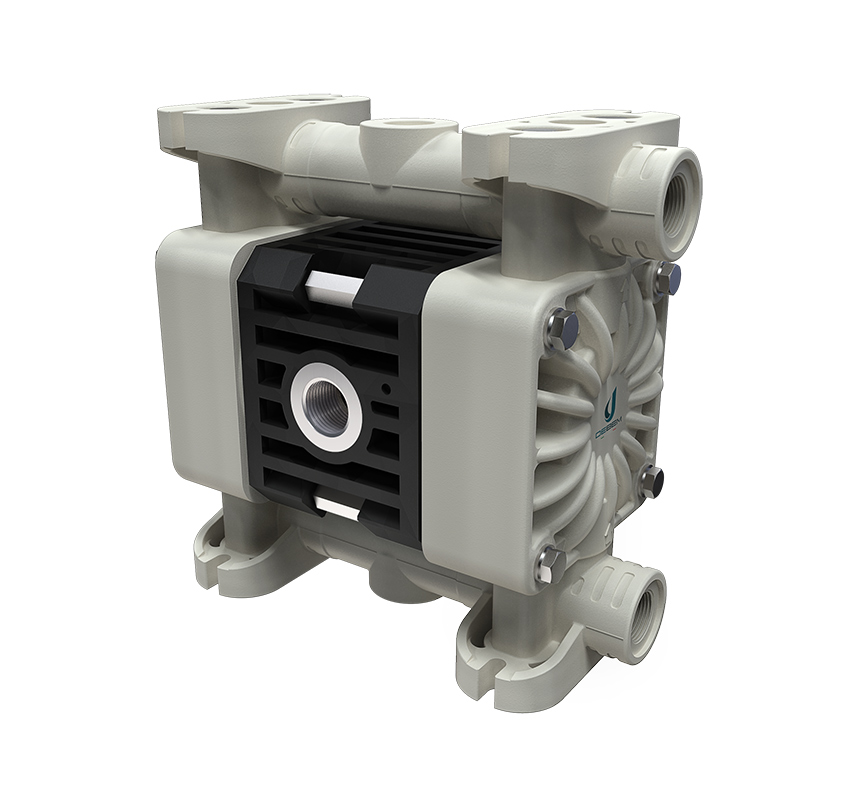

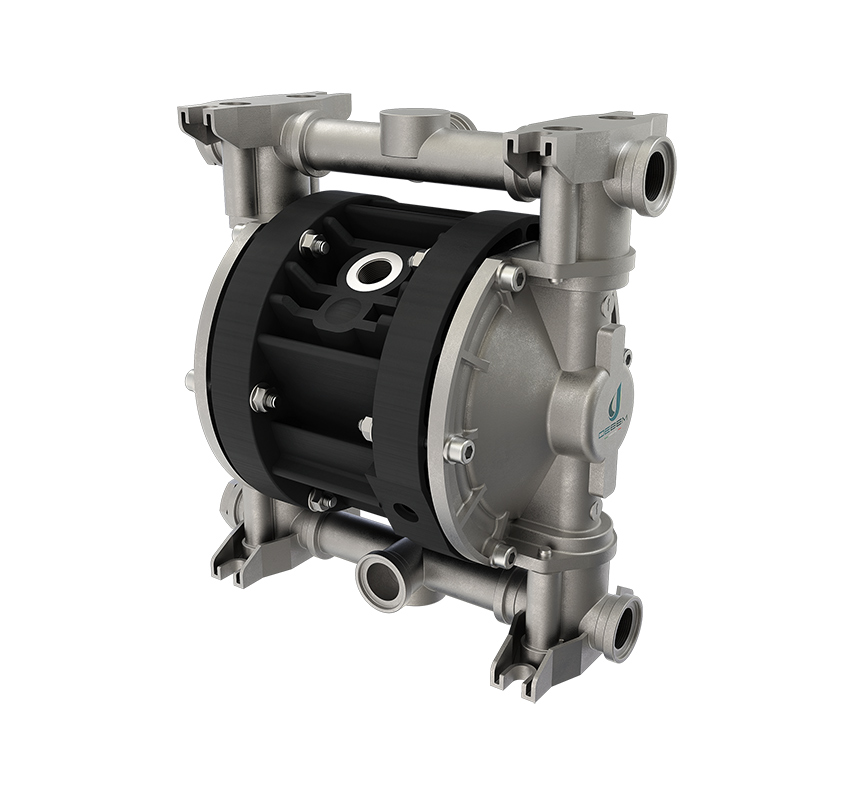

Debem has the right pump for your needs

The use of DEBEM pumps in the Biodiesel sector

Biodiesel is one of the instruments used by the European Community for energy procurement and to reach the targets set out in the Kyoto protocol. Biodiesel is defined by the international CEN specifications with the acronym FAME (Fatty Acid Methyl Esters) with the two different specifications of fuel for transport (UNI EN 14214-2004) and heating (UNI EN 14213-2004).

The Italian production of biodiesel is constantly growing and it has exceeded 400,000 tons per year, compared with a European production of about three million tons per year.

Biodiesel is a form of energy that can immediately contribute to resolving local pollution problems, thanks to the presence of oxygen in its molecule (about 11%). Another benefit is that the combustion is improved and, as it doesn’t contain polycyclic aromatic hydrocarbons or sulphur, it reduces the level of pollutants and dangerous emissions.

Advantages in the Biodiesel sector

A study on a diesel engine run on biodiesel by the UK Health and Safety Institute found that particulate matter (PM10) was reduced by 58%, with a drop of 76% for the most harmful part, the soot, which is more easily absorbed during breathing and which cannot be reduced by catalytic converters. These data are in line with data provided by American studies validated by the EPA (Environmental Protection Agency).

How is it produced? It is produced by pressing oleaginous rape, soya bean, sunflower seeds and through a reaction called transesterification, whereby the origin alcohol component (glycerol) is replaced with methyl alcohol (methanol)

Summary of applications: production and storage of biodiesel