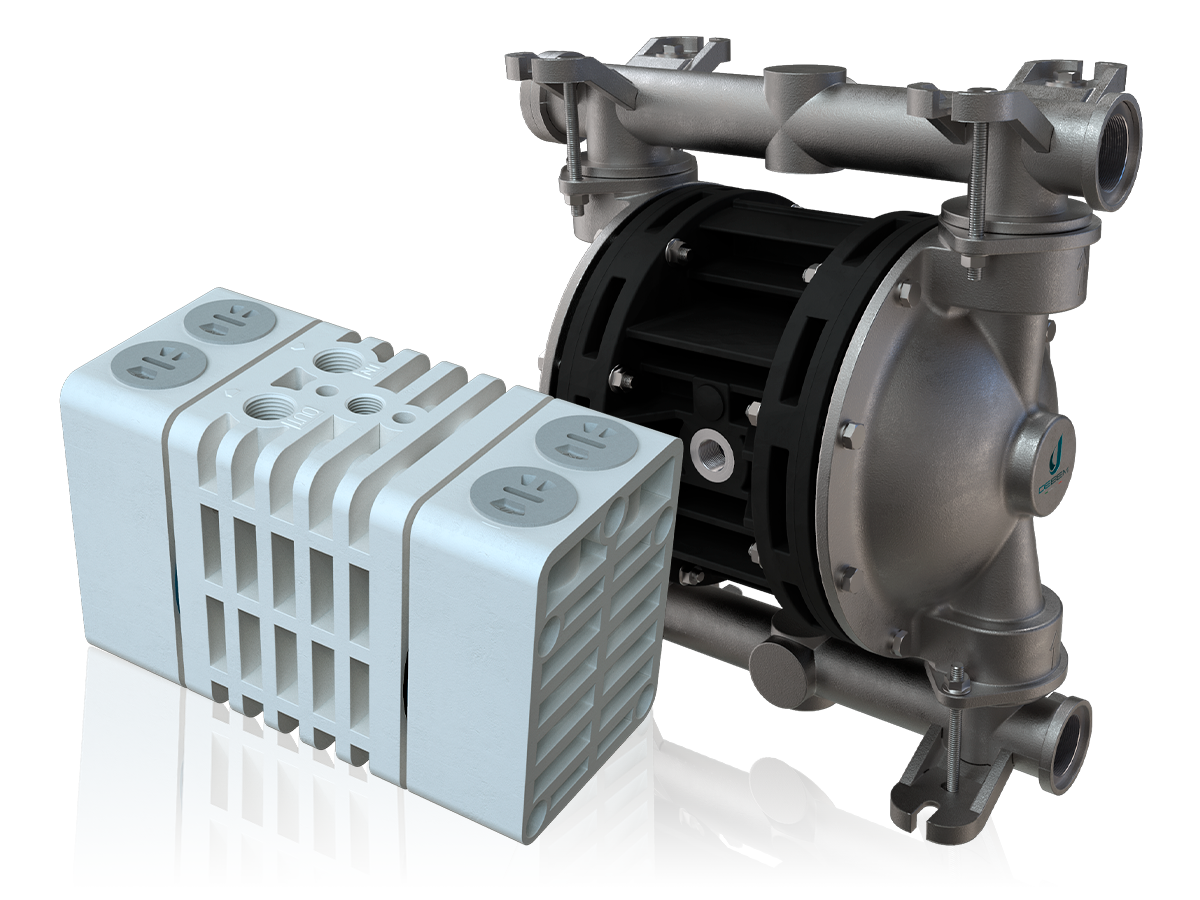

Debem double diaphragm pumps

Debem's double diaphragm pumps are the ideal solution for efficiently, safely and reliably handling high viscosity liquids, even those containing suspended solids.Technical features of double diaphragm pumps

Debem's range of double diaphragm pumps

Every feature has been carefully considered to ensure that Debem's AODD pumps exceed expectations in terms of performance and user-friendliness.AISI 316 stainless steel and PTFE FDA pumps, suitable for the food and sanitary industry.

For more control in dosing and metering applications, allowing full process automation.

Features a unique horizontal fluid circuit, ideal for fluids and solids with different viscosities and sizes.

The materials of Debem's Double Diaphragm Pumps

The materials used in Debem pumps meet the demanding requirements of industrial applications, ensuring resistance, chemical compatibility and safety.

Metal pumps

Characterised by their robustness and durability, they are ideal for the oil, gas and chemical industries. Stainless steel pumps are used in food and sanitary applications, while aluminium pumps are durable and cost-effective for various industrial applications. They are suitable for abrasive liquids, high-viscosity fluids and potentially explosive environments.

Plastic pumps

They offer high chemical compatibility, portability and cost-effectiveness. Polypropylene pumps are ideal for aggressive chemicals and can be used in explosive environments. PVDF pumps are suitable for corrosive and aggressive fluids. Less suitable for outdoor environments due to sensitivity to temperature and UV radiation.

02

Anti-stall pneumatic circuitAn anti-stall pneumatic circuit ensures safe operation without the need for lubricated air

03

Low air consumptionWith the lowest air consumption on the market, Debem pumps optimise air usage, ensuring efficiency.

04

Accurate flow ratesGuaranteed by state-of-the-art certified equipment, providing real and accurate flow data.

05

FEM analysisFinite element analysis ensures pump reliability and durability right from the design stage.

06

Long-life membranesDesigned for maximum stress distribution and mechanical strength, available in a range of materials such as HYTREL®, SANTOPRENE® and PTFE.

07

Quality materialsDebem pumps are made from certified high-quality materials, including reinforced plastic, high-quality aluminium, certified SS 316 and specially treated PTFE.

The applications of Debem diaphragm pumps

Debem's AODD pumps are suitable for a wide range of applications in various industries, including chemicals, water treatment, mining, food processing, pharmaceuticals, mining and more. The pumps are designed to meet the specific needs of each industry, ensuring efficient and safe fluid handling.

Concrete Pumps

Enter

Chemical Pumps

Enter

Paint Pumps

Enter

Galvanic Pumps

Enter

Paper and Packaging Pumps

Enter

Oil and Gas Pumps

Enter

Mechanical Industry Pumps

Enter

Gold Pumps

Enter