Vertical centrifugal pumps represent a cutting-edge approach to mitigating air pollution and preserving air quality. The effectiveness of these processes is closely linked to the availability of reliable and durable pumping solutions. In this article, we will illustrate the areas of use and strengths of vertical centrifugal pumps within industrial purification solutions using scrubber devices.

What are scrubber devices and what role do they play in industrial purification processes?

Scrubber devices are equipment designed to remove harmful pollutants from industrial fumes and to prevent the dispersion of hazardous substances into the air. By employing a specialized liquid solution, these systems efficiently capture and neutralize harmful particles and gases contained in the fumes. The pumping system inside the scrubber allows the liquid solution to be atomised, which, in the form of a wet barrier, absorbs the polluting particles and purifies them before the air is released back into the environment. After absorbing the pollutants, the scrubbing solution in turn becomes waste that can be purified and disposed of safely.

Vertical-axis pumps used in scrubber purification devices

Vertical-axis pumps are frequently used within purification systems operating with fluid recirculation technology. Their function is essential for maintaining system effectiveness and the capture of pollutants. However, the choice of a suitable pumping technology requires careful evaluation of requirements such as construction without mechanical seals, material resistance to chemical liquids or corrosive substances, and flexibility to operate inside and outside the tank.

Advantages of using vertical pumps in scrubber devices

Employing vertical pumps in scrubber systems presents several notable advantages over alternative pumping methods.

- Pump life: thanks to a design configuration without mechanical seals, vertical pumps offer a good degree of wear resistance, which in turn translates into a significant increase in reliability and life span.

- Simplified maintenance: the absence of mechanical seals and the special resistance to corrosive agents minimise the need for maintenance operations while reducing costs and effort compared to other pumping options.

- More efficient installation and operation: the simplified design configuration makes installation and maintenance of the system much easier, minimising the risk of sudden failures and ensuring smooth continuous operation.

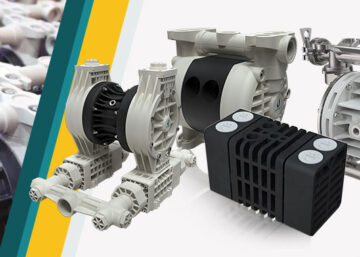

Debem’s IM vertical pumps

Debem’s IM vertical pumps are particularly suitable for powering scrubber systems due to their robust design configuration and excellent resistance to corrosive agents. The use of highly resistant materials, including polypropylene (PP) and polyvinylidene fluoride (PVDF), ensures excellent corrosion resistance and good compatibility with a wide range of aggressive chemicals. The ability to be installed directly inside tanks and the ability to pump fluids with heads of up to 35 metres allows these pumps to adapt to a wide variety of environments and applications, including water treatment, chemical, mechanical, metal and galvanic industries. A further feature of the IM pumps is the absence of internal mechanical seals, a design choice that significantly increases the pump’s service life and reduces the risk of failure, ensuring constant and reliable performance over time.

Reach out to Debem’s sales team for assistance in selecting the vertical pump that perfectly matches your purification system’s requirements. Our experts are committed to offering knowledgeable support, steering you towards the most effective and eco-friendly option.