With over 1 billion metric tonnes of CO2 emissions each year, the European industrial sector represents one of the main environmental threats of our time. Industrial production activities contribute significantly to air pollution, emitting large quantities of greenhouse gases such as carbon dioxide (CO2), methane (CH4) and nitrogen oxides (NOx). The need to reduce these emissions has become a priority for many companies and governments, driving the adoption of cleaner, more sustainable technologies.

Within the energy-intensive production processes we also find all pumping technologies that can be characterised by different levels of efficiency and energy consumption. In this context, double-diaphragm pumps (AODD), thanks to their innovative features, can be highly energy efficient, reducing energy consumption and, consequently, CO2 emissions associated with production processes.

The adoption of more sustainable pumping technologies, such as AODD pumps, is therefore a concrete strategy for companies aiming to reduce their environmental impact and comply with increasingly stringent emission regulations.

The role of AODD pumps towards sustainability

Double diaphragm pumps (AODD) play an important role in helping a manufacturing company achieve its sustainability goals. Due to their special design features and versatility, these types of pumps offer numerous environmental advantages over conventional pumps. AODD pumps can reduce energy consumption and minimize product losses, thus helping to reduce overall emissions within the industrial production process. Furthermore, AODD pumps can handle aggressive and viscous fluids without compromising system integrity, making them ideal for applications in critical industries such as chemicals and pharmaceuticals. A further advantage of AODD pumps is their low maintenance requirements and resistance to wear. These features significantly extend product life, thus reducing waste and potential deposits over time.

Sustainability characteristics of AODD pumps

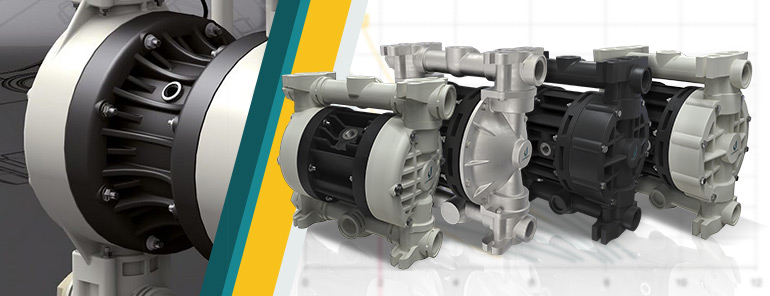

AODD pumps are characterized by several features that make them particularly suitable for supporting sustainability goals within production processes.

- Materials of construction: AODD pumps are made of strong, durable materials that reduce the need for frequent replacement and lower maintenance costs.

- Energy efficiency: AODD pumps run on compressed air and reduce the need to draw on alternative energy sources. Running on compressed air means reduced consumption compared to traditional pumps, resulting in lower energy costs and carbon emissions.

- Versatility: AODD pumps can handle a wide range of fluids, including those with high viscosity and solid particles, without risk of damage or contamination. In this way, the same pumping technology can be adapted to different contexts of use.

- Reliability: The robust design and ability to operate in harsh conditions make AODD pumps extremely reliable, reducing downtime and improving operational efficiency.

How can double diaphragm pumps meet sustainability goals?

AODD pumps can significantly contribute to achieving sustainability goals through various ways:

- Reducing emissions: due to their energy-efficient characteristics, AODD pumps help reduce CO2 emissions associated with the energy consumption of industrial processes. Compressed air operation means reduced consumption compared to traditional pumps, resulting in lower energy costs and carbon emissions.

- Minimising waste: AODD pumps are designed to minimise product losses during fluid transfer, improving overall efficiency and reducing waste. Good durability characteristics and reduced maintenance requirements contribute to greater product longevity, reducing waste and potential deposits over time.

- Regulatory compliance: Using AODD pumps can help companies comply with increasingly stringent environmental regulations, avoiding penalties and improving their environmental reputation. These pumps support regulatory compliance in industries such as pharmaceuticals, food and electronics manufacturing, maintaining purity levels and preventing contamination.

- Innovation and continuous improvement: adopting advanced technologies such as AODD pumps drives companies towards continuous innovation, improving processes and reducing environmental impact in the long term. Their reliability and low maintenance requirements ensure minimal downtime and operational interruptions, allowing companies to maintain high levels of productivity and meet production targets efficiently. Improved productivity not only increases profitability, but also reduces resource consumption per unit of production, promoting economic and environmental sustainability.

AODD pumps are an effective and sustainable solution for industries that aim to reduce their environmental impact and achieve sustainability goals even in the short term. Thanks to their energy efficiency, reliability and versatility, these pumps are a key component in improving industrial processes and reducing emissions.

Debem, a leading manufacturer of centrifugal and double diaphragm pumps, is committed to providing innovative solutions that support companies on their path to a more sustainable future.