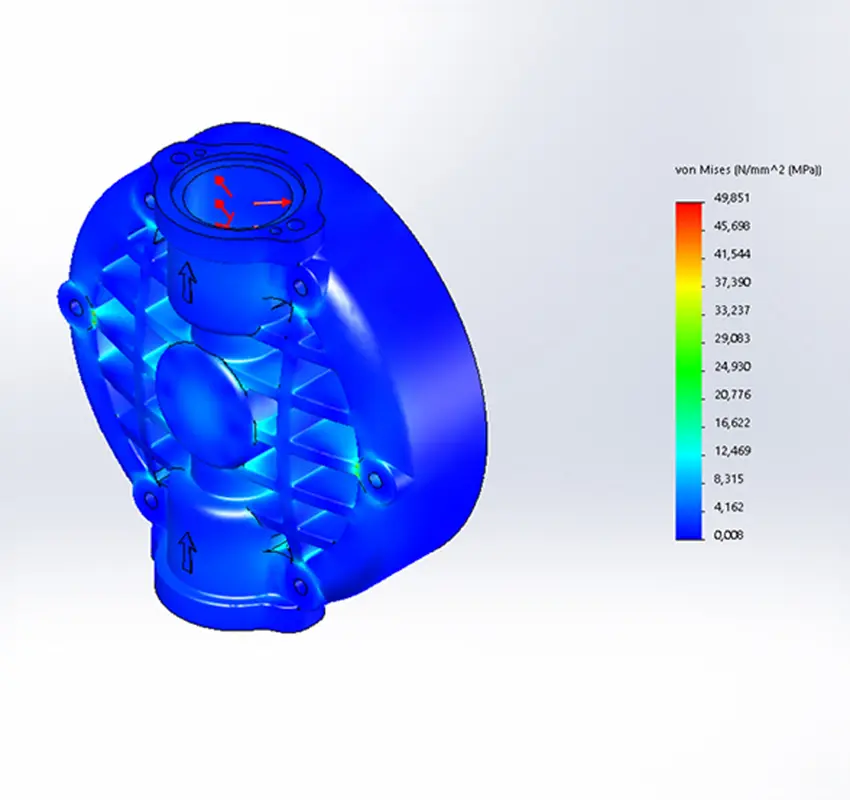

FEM analysis

The Finite Element Analysis, FEA; (or FEM – Finite Element Method) is a computerised method used to simulate the reaction of a mechanical part to vibrations, heat, fluid flow and other physical interactions. The finite element analysis can be used to predict the risk of failure, speed of wear and correct operation of a product right from the design stage. Even though it is referred to as an analysis, the FEM is an excellent tool to predict the behaviour of a product during its future use.

How does it work?

The FEA divides a whole object into a high number (from thousands to hundreds of thousands) of finite and discrete elements, with a tetrahedral shape. The mathematical equations allow the behaviour of each element to be predicted. The process predicts the reaction of the finished part, through the sum of all the individual behaviours, triggered by the surrounding conditions

By combining the response of the individual elements, the computer is then able to provide the response of the object in its entirety; answer that will depend on the boundary conditions:

- Stresses acting on the piece

- Constraints

- Material

This process allows to know in advance the final behavior of the component and, consequently, its limits of use.

The case studies of FEM Analysis

The most common stress conditions, simulated and calculated on the piece:

- Mechanical stress

- Mechanical vibration

- Fatigue

- Heat transfer

All this integrates the meticulous traditional quality control, reducing the waste percentages of the supply pieces and consequently the possibility of errors during the control phase, and ultimately minimizing the possibility of early breakages occurring during the use of a Debem product.