Industrial pumps

Debem’s team of engineers have designed, developed and produced five different families of pumps, to meet all our customer’s requirements. Debem’s industrial pumps have unique and patented components. They are custom-assembled and built with materials and components that make them ideal to be used in multiple applications.

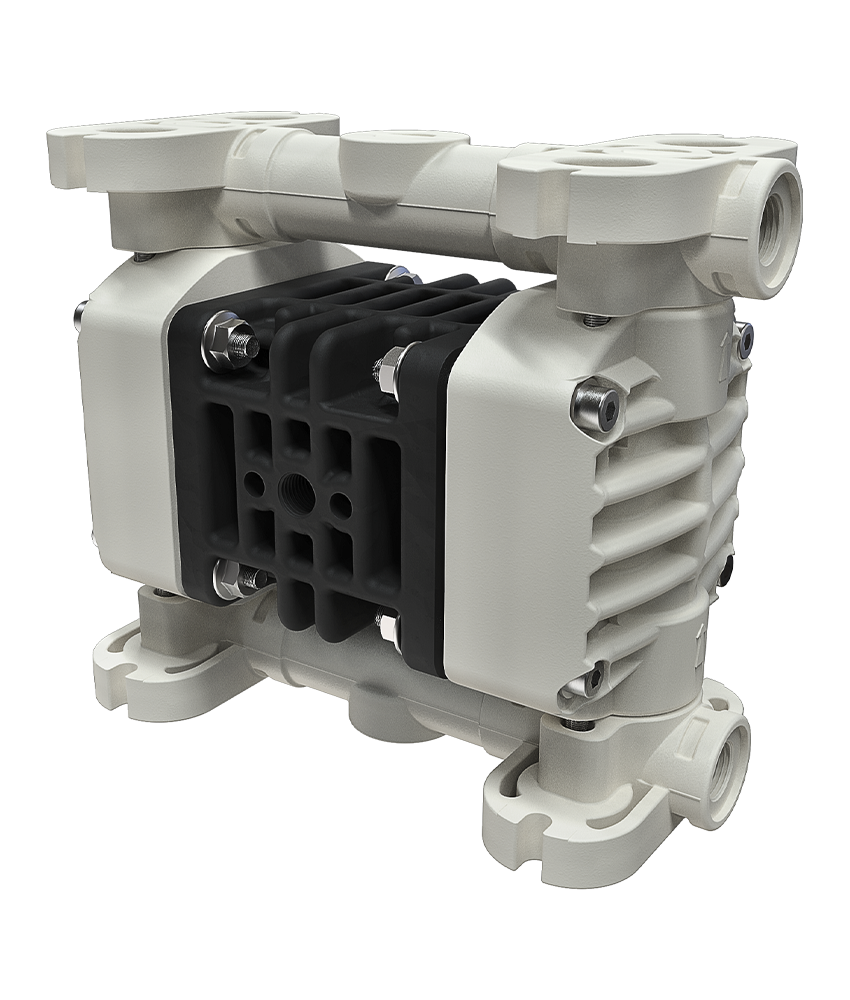

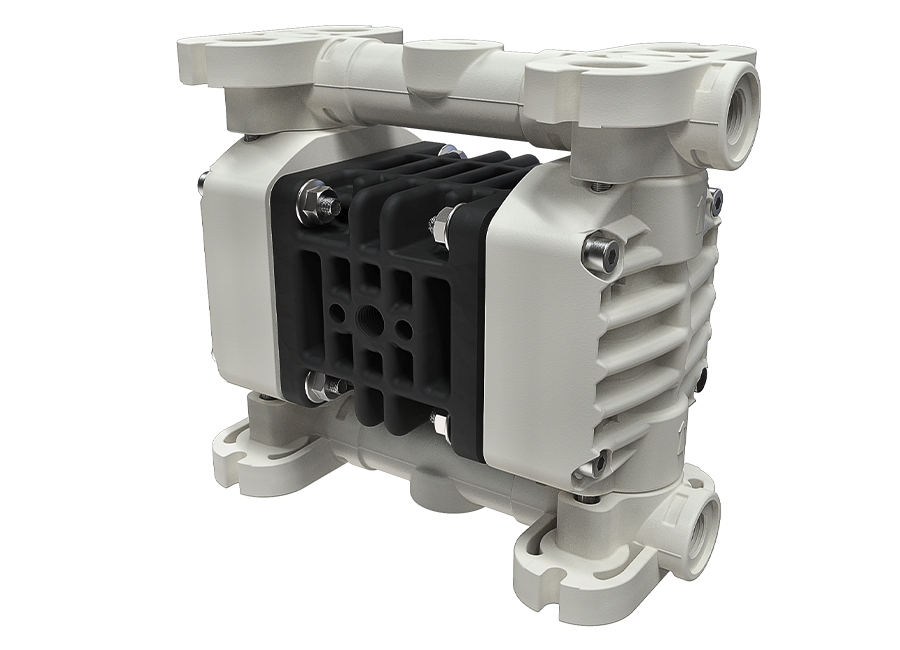

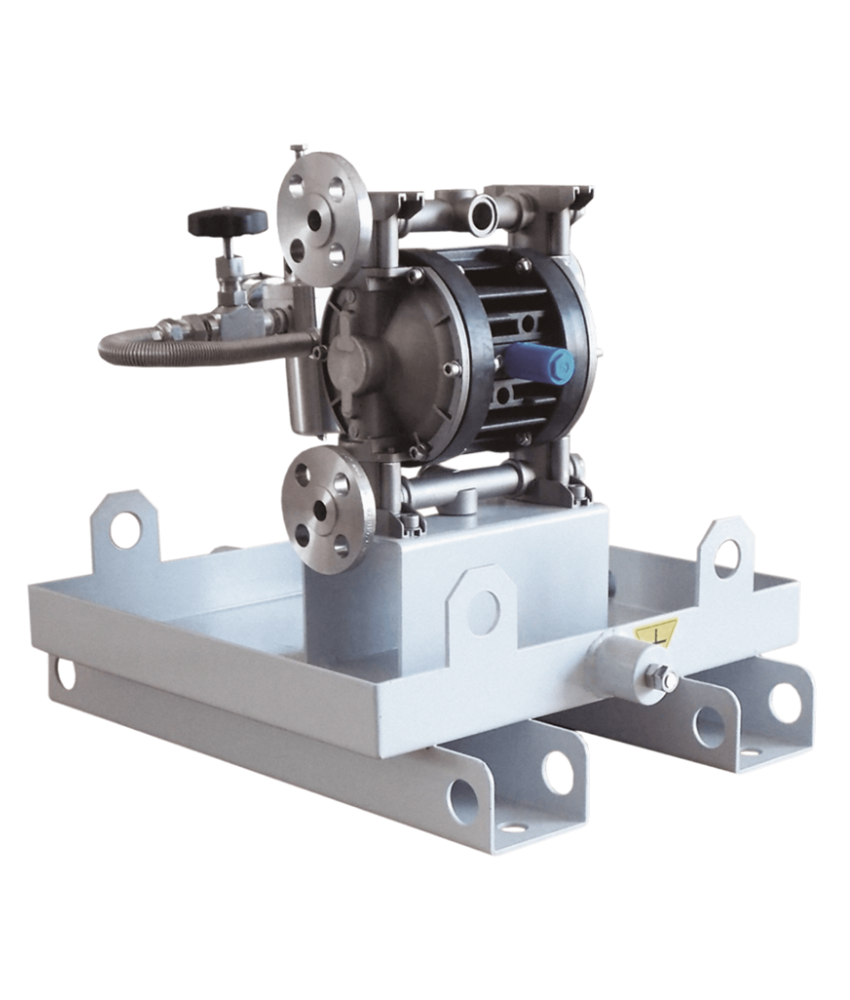

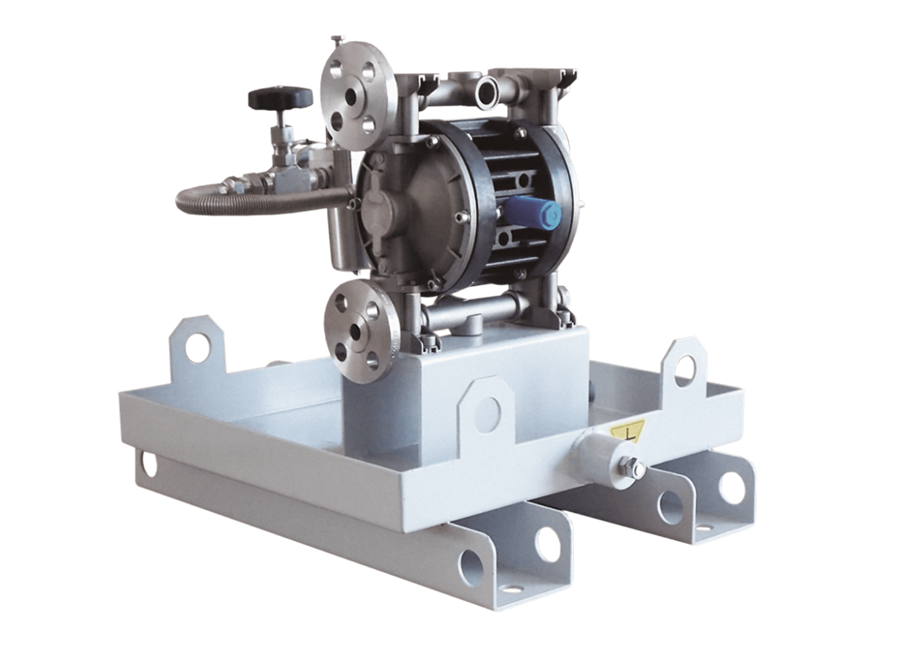

Our air operated double diaphragm pumps and volumetric pumps are sturdy and powerful, self-priming (dry negative vacuum), also in demanding conditions. They can transfer liquids with high viscosity, even with suspended solids. ATEX – IECEx certified. Built with plastic (PP – PVDF) and metal materials, such as aluminium and AISI 316L steel.

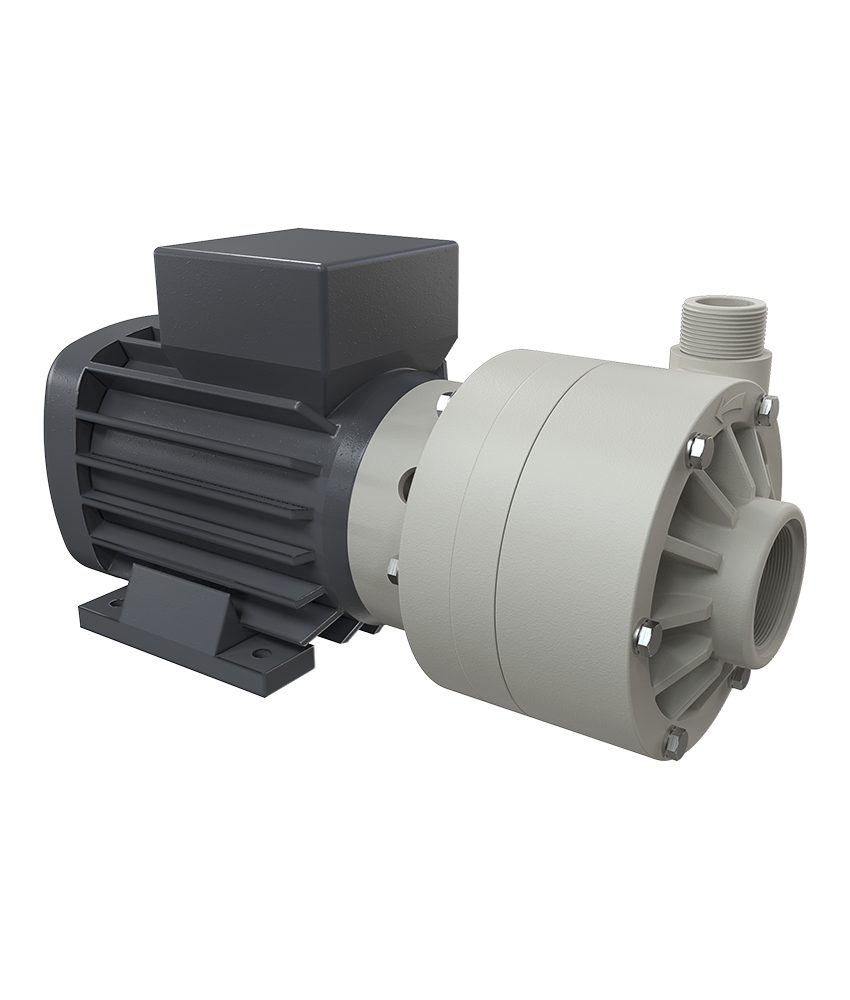

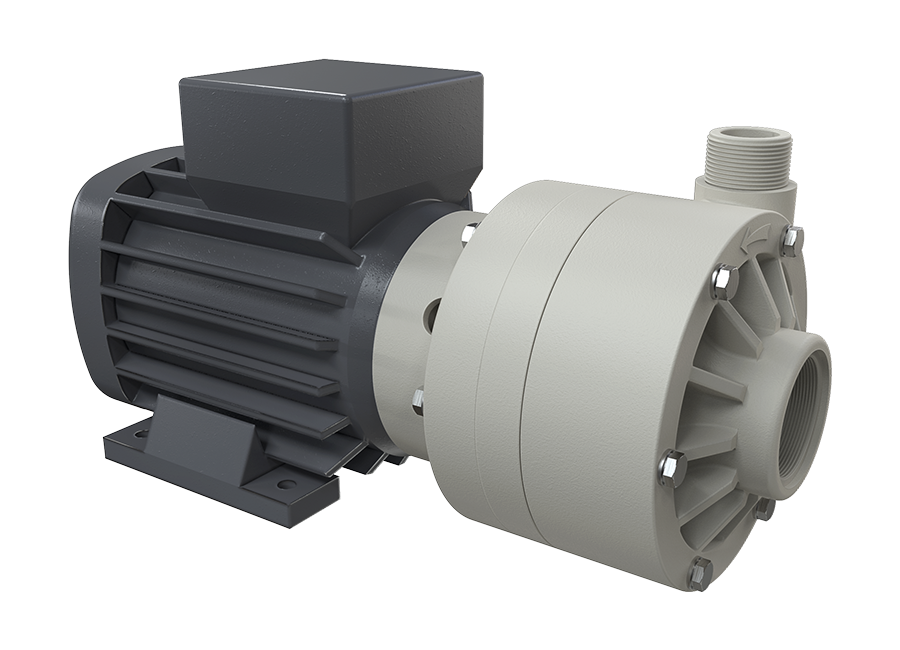

Centrifugal pumps with vertical axis (in polypropylene or PVDF) designed for fixed installations with the pump immersed in the tank. These pumps are ideal for pumping quickly high quantities of corrosive, or very dirty fluids with suspended solids. Magnetic drive electric centrifugal pumps (in polypropylene or PVDF) that are particularly suited for pumping corrosive fluids.

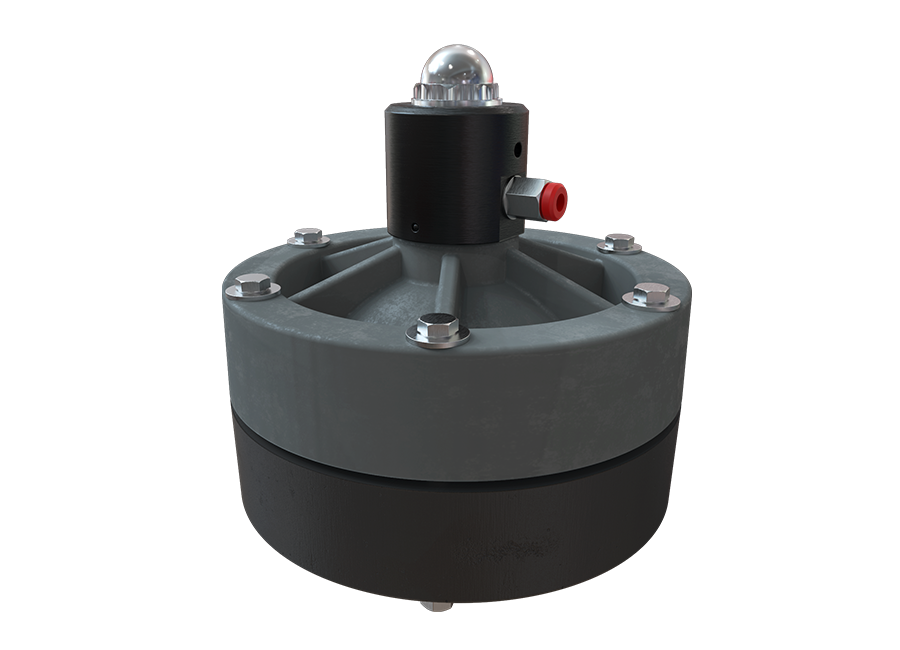

They minimise the pulsations of the fluid and the consequent vibrations, or water hammer, to protect the process equipment.

Customers can choose the type of motor to apply to the drum transfer pump: electric or pneumatic. They can also be supplied with a range of accessories, such as for example flow meters, dispensers, hoses and filters.

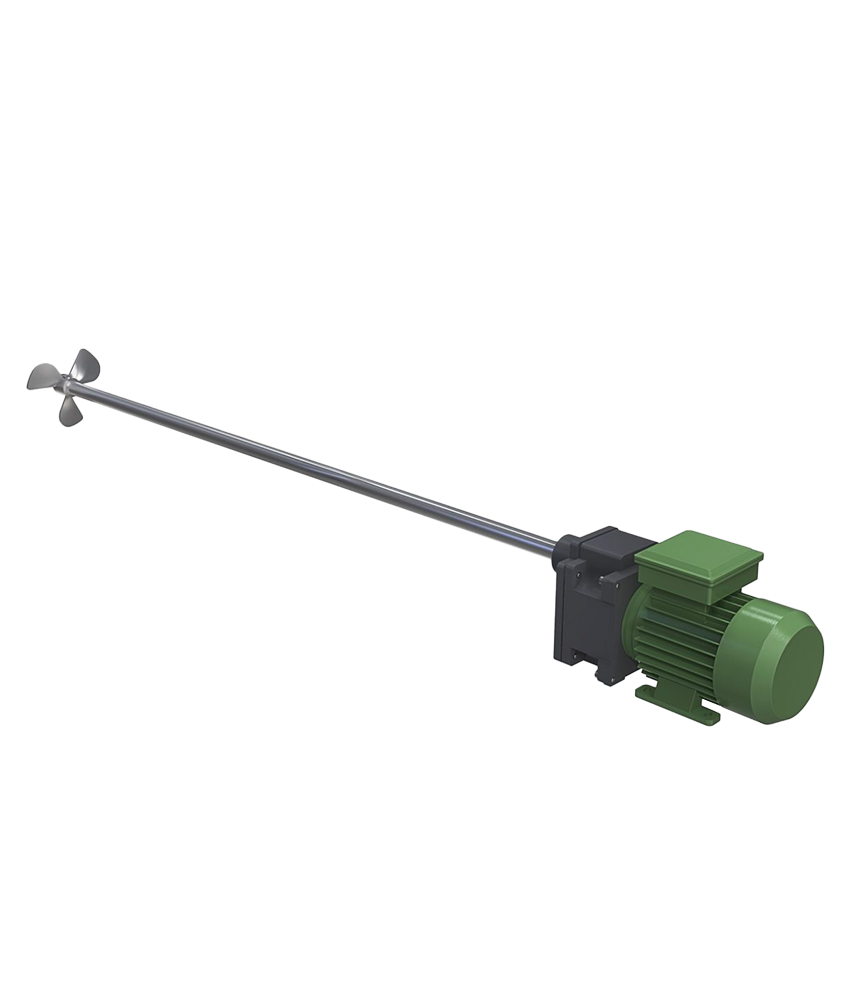

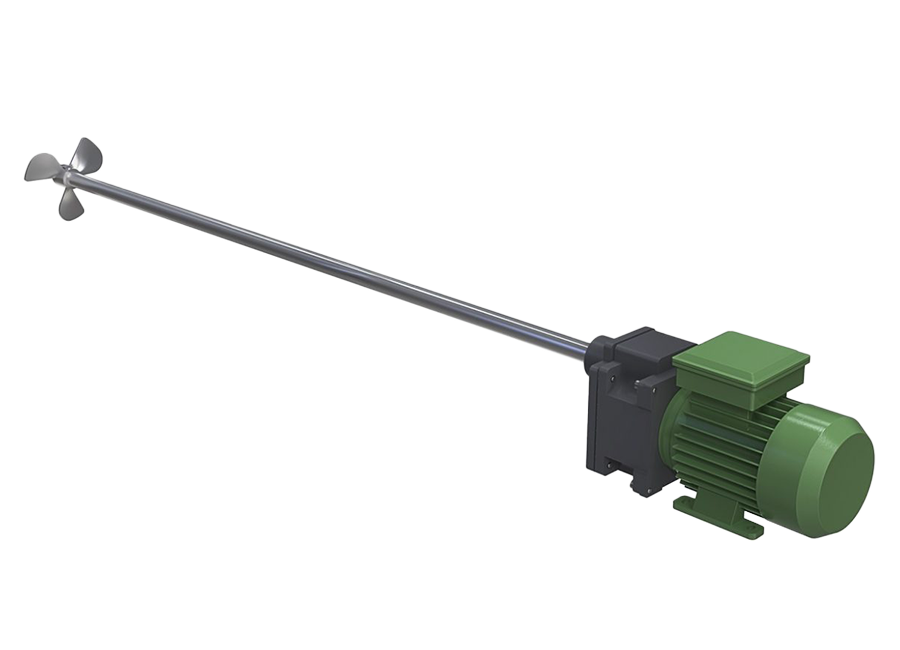

Debem also produces submerged mixers (in plastic and stainless steel) and peristaltic pumps.

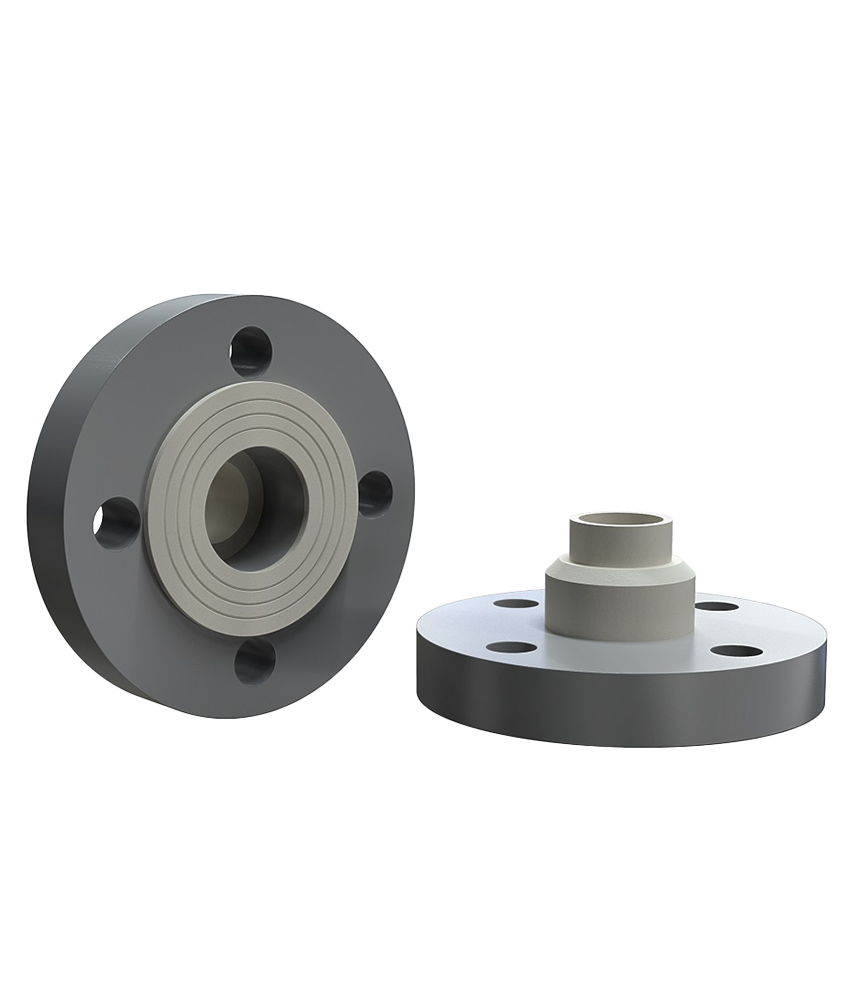

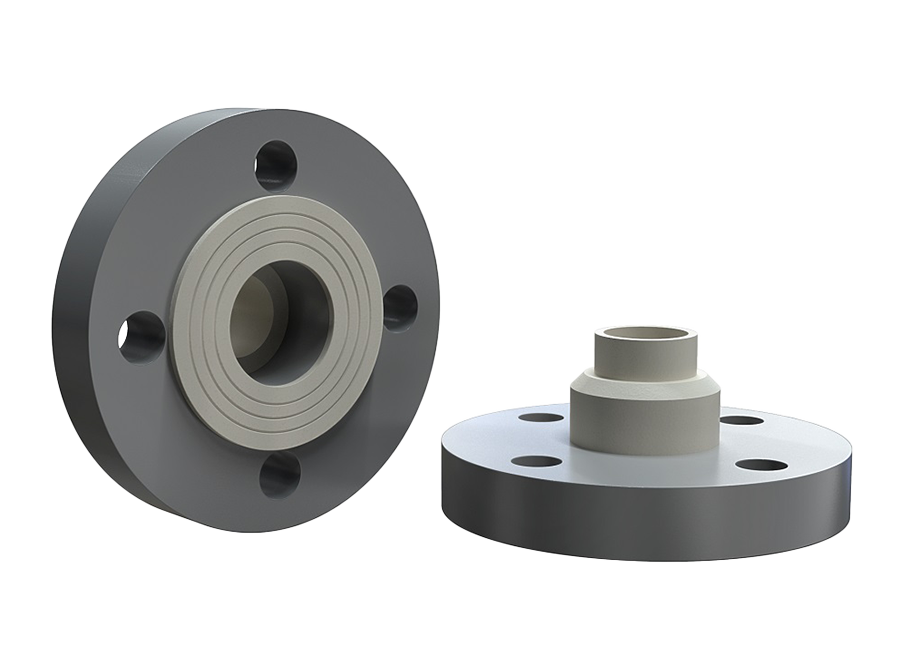

Debem’s production includes a whole range of pump accessories, designed and built in-house, for the pumps. They include products for filtering, dosing, remote control of the pump and to move the pump and connect it to systems.

DEBEM realizes turnkey pumping solutions that are adequately tested and tested. The tailor-made solutions are complete with all the accessories that make them suitable for application in any destination plant.

Our certified quality

Ask for more information

Discover the Debem pumps catalogue!

With over 40 years of experience in pumping and liquid transfer systems Debem is at the cutting edge of the sector and its core business is the design and production of industrial pumps for highly demanding environments. Debem produces different types of pumps, volumetric (air-operated double diaphragm: CUBIC – BOXER – FULL FLOW and REMOTE CONTROL), electric centrifugal (MB SERIES horizontal centrifugal, IM SERIES vertical centrifugal, DM SERIES magnetic drive centrifugal) and drum transfer pumps of the TR SERIES. All Debem’s industrial pumps are fully designed and produced in-house and the company holds the patents to its designs. Debem guarantees prompt delivery times thanks to computer management system that monitors the minimum stock of every component of the pumps of the pre-assembled parts. Similarly all the spare parts are ready in stock and available for customers to buy individually or as a kit.

Certified quality and innovation

The quality certification procedures set out the tests that must be carried out on every single industrial pump during the assembly when dry, and during their operation with a fluid. We therefore don’t limit our testing to samples of the production. The data collected are used to check that the pumps comply with the necessary parameters. Debem can count on its own new-concept test bench, with state of the art certified instruments, designed to test and certify the parameters of its own products and the efficiency of Debem’s industrial pumps, in compliance with the latest applicable standards and in line with the new European project for INDUSTRIA 4.0. One of our company’s strengths is the development of our in-house R&D department, which is quite unusual for a small company, but something that has certainly borne its fruits. The department was initially introduced to improve existing products, by researching the use of new materials (that led to the creation of an innovative molecular stabilisation process for polypropylene and a treatment process for PTFE, to increase its elasticity and resistance to fatigue and wear), rationalising the spaces used, optimising the existing technology and reducing costs without affecting the already high quality standards. The research project has allowed us to develop highly innovative industrial pumps, such as the CUBIC – BOXER and FULL FLOW series.