The needs of the biopharmaceutical sector

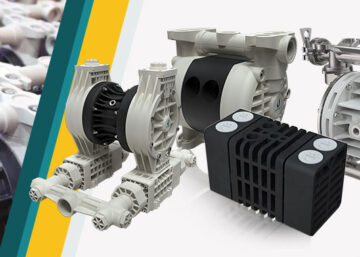

Double diaphragm pumping technologies can be used in many applications with complex fluid transfer needs such as the biopharmaceutical industry dedicated to the production of vaccines and antigens. In this post we want to deepen the use of AODD pumps in applications that involve the handling of materials sensitive to contamination, highlighting advantages and strengths in terms of performance and safety.

The use of a diaphragm pump protects the liquid from the risk of being subjected to aggressive cutting and minimizes the risk of leaks that could lead to contamination of the product and the surrounding environment. The fluid transfer needs within the biopharmaceutical industry are very diverse and can include blood, plasma and by-products, cell cultures, vaccine manufacturing solutions, disinfectants and sanitizing solutions, pill coating solutions, care solutions eye drops or eye drops, vitamins, creams and lotions.

Advantages of diaphragm pumps in the biopharmaceutical sector

In recent decades, double diaphragm pump technology has evolved significantly becoming a reliable solution capable of meeting the complex fluid transfer needs present in the biopharmaceutical industry. The concept of diaphragm is not new in the biopharmaceutical industry due to the high use of diaphragm valves due to the good holding characteristics of the product and the high ease of cleaning. To these features, the double diaphragm pumps add the additional benefit of a simple construction configuration without mechanical elements that could cause risks of failure or wear.

Within any production process in the biopharmaceutical sector, there are strict protocols aimed at minimizing the cases of product losses, encrustations, or cross contamination. In this sense, the double membrane technology can offer a series of advantages in many crucial areas.

Maintenance and purity of the transported fluid: The use of AODD pumps allows you to manage the filling and emptying processes at the same time, eliminating the need to resort to gas purging systems that could cause potential contamination of the transported fluid.

Versatility of pumps within the production chain: Pharmaceutical processing requires the completion of very complex industrial operations. One of these is the transfer of fluids along the entire length of the production chain. AODD technology guarantees high versatility to perform transfer operations reliably and efficiently at any level of the production hierarchy.

Dry running: AODD pumps excel in this type of application because they have design features that allow them to self-prime and run dry without running the risk of damage. This type of design design makes them suitable for managing the Clean in Place (CIP), Sampling, Filtering and Separation processes present very frequently within the biopharmaceutical sector.

Cleaning and Maintenance: The cleaning and maintenance of AODD pumps is very simple thanks to the construction configuration. Within the processes that require high hygiene standards, AODD pumps are designed to be subjected to automatic cleaning cycles (CIP) thus eliminating manual interventions and the risk of contamination. The simplicity of construction and the absence of mechanical parts inside the pump body also reduce the risk of damage and wear of the materials with optimization of intervention and maintenance costs.

Conclusions

Thanks to their simple yet innovative design, double diaphragm pumps have proven to be able to:

- Constantly meet the needs of complex industries.

- Operate efficiently, reliably and safely in a wide range of critical fluid handling applications.