A self-priming pump is a specific type of fluid pump that needs to be filled with a liquid within the pump cavity or pump body to start the pumping process. This design feature provides an opportunity to increase operating efficiency in process plants where pumps are used for a series of repeated but intermittent operations.

The constant presence of fluid in the pump body enables the pump to better handle so-called “air pockets,” or accumulations of air bubbles in the pump’s operating mechanism that can impair its proper operation. In practice, self-priming pumps are previously filled with the relevant fluid through a small port located on the pump body (the chamber where the impeller is located). After this operation, the pump can be operated, triggering turbulence that allows the fluid to rise and “clear” the piping of air.

DEBEM’s self priming pumps

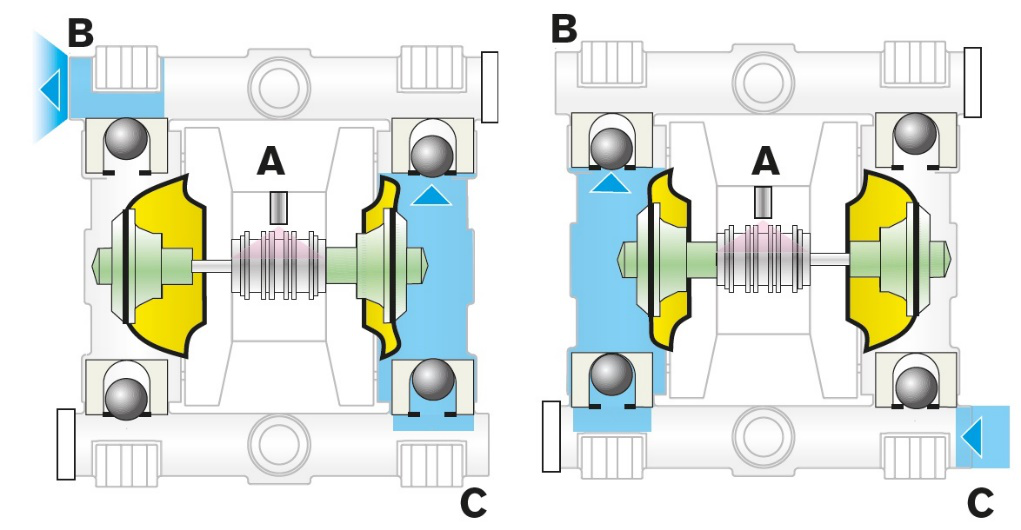

One of the most common design methods to induce the priming process involves the following steps:

- Creating a reservoir parallel to the utility line, with a volume equal to or greater than the amount of liquid needed to fill the suction line. This tank allows the pump to release air from the pump body and suction line during the priming cycle, replacing it with liquid from the tank that is mixed with the remaining air.

- Insert a check valve in front of the pump so that filling operations do not have to be repeated each time the pump needs to be operated.

The “self-priming” capability of this type of centrifugal pump comes from the ability of the tank to hold the liquid after its initial priming. In describing the concept of self-priming, reference has always been made to the centrifugal pump type. However, there are several types of pumps that can be associated with this term, specifically positive displacement diaphragm pumps, peristaltic pumps, and lobe pumps.

Debem offers a range of fully air operated double-diaphragm positive displacement pumps capable of complete self-priming features. In the specific case, the operation of the Cubic and Boxer lines of pumps makes the parallel tank inside the pump body unnecessary. This can be considered a tremendous advantage in applications where limited space conditions require the use of a pump with a smaller size than the standard size that characterizes reservoir models.

Main applications of self-priming pumps

Self-priming pumps are used in many application areas. Specifically, within the food and pharmaceutical industry, pumps are placed within process lines to perform various operations such as:

- Move liquids, ingredients, raw materials and semi-finished products through process lines.

- Pump CIP (clean-in-place) fluids to perform cleaning and sanitizing operations on pipes and plant components.

- Move fluids from one storage vessel to another.

- Perform drum and tank emptying operations.

Self-priming pumps also find easy use within the construction, agricultural, and water treatment sectors when it is necessary to be able to properly extract and pump water while at the same time maintaining high plant efficiency conditions.

Advantages of using self-priming pumps

The main advantages of a DEBEM self-priming pump are many and can be summarized in the following points:

- Pumps with self-priming features ensure a higher suction height, compared with classic centrifugal pumps that are capable of sucking liquid from a maximum height of 5-6 meters.

- This type of pump can handle a wide variety of liquids and is the ideal solution for handling special fluids such as slurries, corrosive liquids, and liquids with suspended solids.

- This technology is Ideal for performing frequent and intermittent pumping operations, as pump priming steps at start-up are eliminated.

- DEBEM pumps do not include a reservoir inside the pump and therefore can feature smaller dimensions than standard pumps.

- Self-priming pumps, compared with submersible pumps, have maintenance features that are easier to handle because there is no need to operate within a confined space or within a liquid.

Choosing the right pump for your needs

With this article, we have defined and illustrated the advantages of self-priming pumps. If you are interested in purchasing a DEBEM self-priming pump get in touch with our sales department now. A knowledgeable team will guide you in choosing the technology best suited to your application needs.