The diaphragm pump, also called AODD (Air Operated Doube Diaphragm) is a type of double diaphragm positive displacement pump operated by using compressed air. The diaphragm pump employs a pneumatic valve that directs compressed air back and forth between the two sides of the pump.

Diaphragm pumps are capable of handling liquids with various levels of viscosity as well as liquids with suspended solids. This type of pump, thanks to the special design configurations and type of materials used, is also capable of safely and efficiently handling particularly aggressive chemicals.

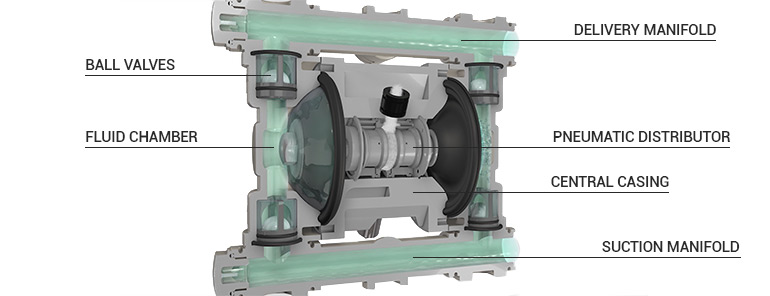

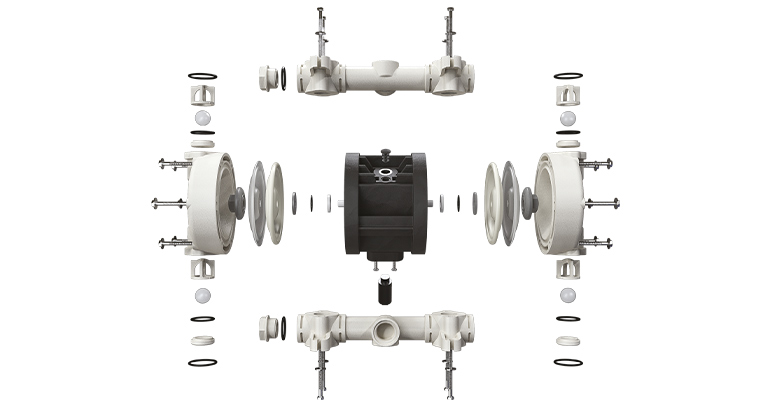

The components of a diaphragm pump

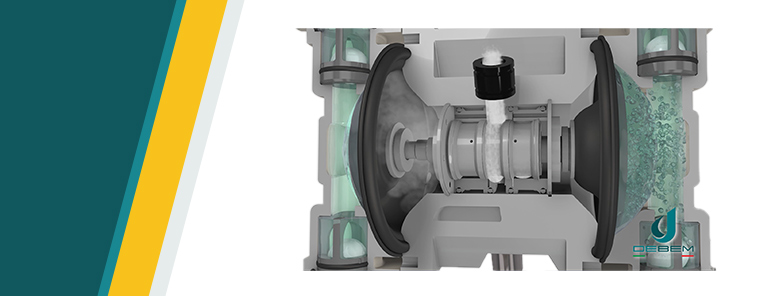

The main components that constitute and regulate the operation of a double diaphragm pump are as follows.

- The Central Body: includes the inlet and outlet of the supply air and the pneumatic exchanger, which provides alternating pressure to the air valve and contributes to the movement of the membranes and at the same time to the pumping action. The pneumatic exchanger, patented by Debem, is a key element in pump operation. This component consists of an outer cylinder that is itself divided into three sections. Compressed air enters the middle section and escapes into the chambers behind the membranes through the two side sections. The pneumatic exchanger also includes a spool, which, moving along the axis, alternately directs air precisely to the two membranes, and a shaft, on which the spool runs and to which the membranes themselves are attached.

- The Fluid Chambers: house the volumes within which fluid is drawn in and pumped out. The fluid chambers include the membranes (green and yellow in the image below) and sometimes include the housing of balls having a similar function to the inlet and outlet check valve. A vacuum is created inside the chamber where diaphragms alternately draw in fluid and push it out from each side to create the pumping action.

- Manifolds: provide the connection interface to the system and are attached to the outer chambers to provide a seal while at the same time creating a fluid flow path. Sometimes they include ball housing that has check valve functionality to prevent the sucked-in fluid from returning to its starting point.

- The air valve: directs compressed air into the chambers and helps move the membrane assembly. At the same time, the air valve, directs compressed air into the opposite chamber allowing it to be discharged to the atmosphere through the exhaust port located in the central block.

- The diaphragms: available in a wide variety of materials and designs act both as a barrier with the task of separating the fluid side of the pump from the air side and contextually to create the pumping action through their expansion.

The different components of double diaphragm pumps, while maintaining the same operating principle, may have different arrangements depending on the size or series of the pump to which they belong.

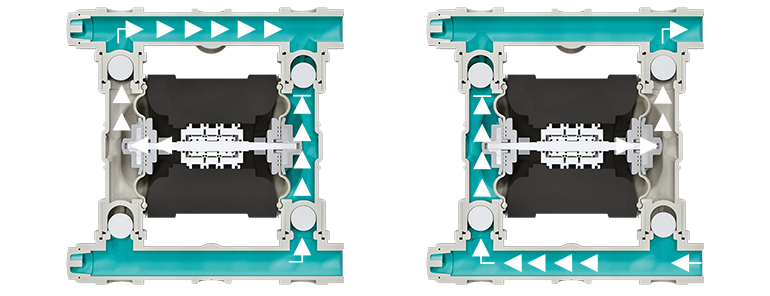

The operation of a diaphragm pump

After delving into the main components of diaphragm pumps, it is possible to analyze their operation. As mentioned earlier, the entire operating cycle of an AODD pump is based on the use of compressed air as the driving fluid. AODD pumps use two flexible membranes mounted on a shared shaft that repeatedly moves back and forth to pump fluids in and out of the pump’s fluid chamber. This movement creates a vacuum, which allows fluid to enter through a suction port.

The air exchange cycle in double diaphragm pumps

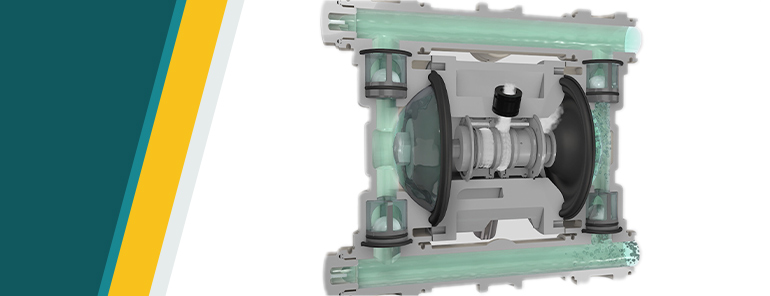

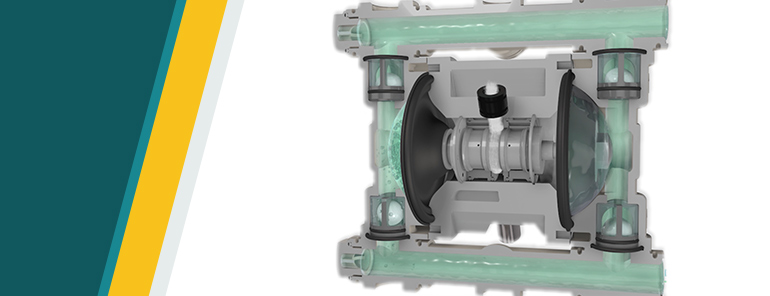

The exchange cycle essentially consists of three phases that are repeated alternately for each chamber.

- Stage 1: The air, passing through the bore in the pump body, arrives at the central ring, where through a series of passages between spool and outer ring it reaches one of the two “air chambers” (in the figure the path is highlighted in red and the air chamber in blue color). The diaphragm, driven by air pressure, expands and moves the liquid into the manifold. The correct direction is ensured by the balls below, which, by gravity, close the passage, preventing the liquid from falling out.

- Stage 2: In the second phase, the spool, pushed by air, beats on the opposite side in the pneumatic exchanger, sliding along the shaft, and sends the other air chamber under pressure.

- Stage 3: In the third phase, called the unloading phase, the air chamber of the membrane that was previously under pressure now sees an open passage to the external environment. The pull of the opposite membrane, which is inflating, retracts the membrane at the same time creating a vacuum in the fluid chamber, which allows the fluid to rise and fill. At the same time, the cycle restarts by repetition, within the second chamber of the action described in step 1.

Most Debem products, provide for a supply pressure range between 2 bar (minimum) and 8 bar (maximum), although there is evidence that pressures even lower than 1 bar succeed in triggering some models.

The Installation of a Double Diaphragm Pump

After delving into the modes of operation of diaphragm pumps, it is possible to define the different modes of installation. The latter include the following modes.

- Self-priming installation: The diaphragm pump is positioned above the level of fluid and can aspirate it, even starting from dry, when it has no liquid inside. The distance between the pump and level of fluid results in loss loads. If the pump is not potted, the maximum height at which the fluid can be aspirated cannot exceed 6 m, while if the pump is potted, we can reach 9.5m.

- Installation with split suction and delivery: In some applications, two fluids need to be pumped, but there is not enough room to accommodate two separate pumps. Debem offers the opportunity to customize its pumps by splitting both delivery and suction. This means that with the same pump you can pump two fluids, for example of two different colors. The fluids, however, need to have similar viscosity and density characteristics.

- Under head installation: Installations where the pump is below the level of fluid.

- Installation with split suction: When there is a need to transform the pump into a mixer, it is possible to use it this way. Only the suction manifold on the pump will be split, while the delivery will remain intact. This will allow the pump to mix the two fluids.

- Immersed installation: In some cases, for example, when emptying wells, the pump can be immersed directly in the water.

- Drum transfer installation: The smallest cutting pumps can be directly located on the drums which need to be emptied.

The importance of choosing the right AODD pumps

AODD pumps can handle a wide range of fluids, flow rates and viscosities and can operate efficiently within a wide variety of application areas. Debem designs and manufactures double diaphragm pumps to meet the challenges of industrial sectors efficiently and safely around the world. Debem provides the expertise of its technical and sales team both to support the needs of choosing a new pump and to provide useful information and advice on the range of accessories or replacement parts.