In a few easy steps, damaged or worn parts on a centrifugal pump can be checked and, if necessary, replaced, or preventative measures taken.

How to disassembly a centrifugal pump. Only after ensuring that the pump has been cleaned internally and there are no dangerous substances, proceed as follows. Debem Srl takes no responsibility for damage to property or injury to people, arising from the implementation of the following instructions in the absence of the obligatory environmental and operator safety requirements.

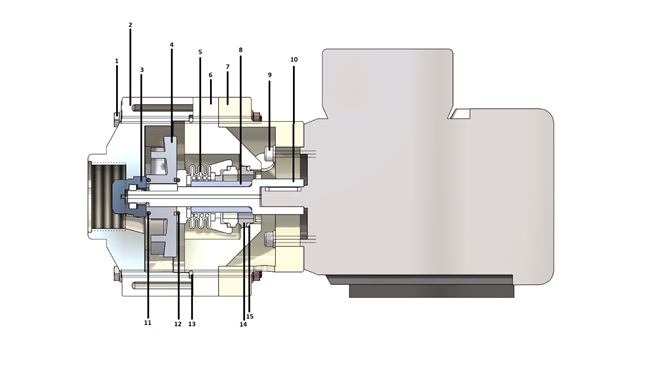

DISMANTLING A HORIZONTAL MB CENTRIFUGAL PUMP WITH BELLOWS SEAL

Dismantling a horizontal MB centrifugal pump with bellows seal, is simple. These are the steps to follow:

1) disconnect the electrical wires entering the electric motor cover

2) disconnect the circuit pump

3) remove the screws (1)

4) uncouple the pump unit (2) and o-ring (13)

5) unscrew the caps (3), making sure you secure the impeller using a soft belt, so as not to damage the paddles

6) extract the impeller (4) from the shaft (10), taking care with the seal o-ring (11 and 12)

7a) In the case of MB 80/130 – TS pumps, extract the mechanical bellows seal (5) together with the metallic cylinder (8) and the silicon ring including its o-ring (14 and 15)

7b) In the case of MB 130/180 – TS pumps, extract the mechanical bellows seal (5) and the silicon ring including its o-ring (14 and 15)

8a) In the case of MB 80/100 – TS pumps, uncouple the seal support flange (6) from the remaining elements

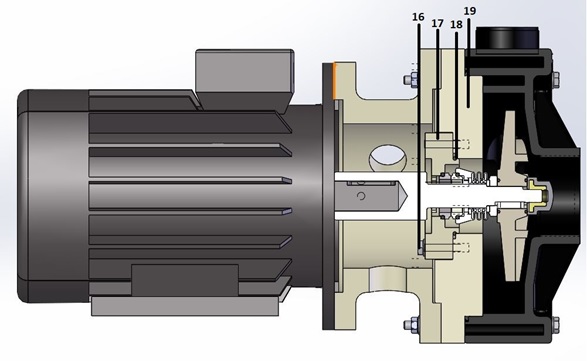

8b) In the case of MB 110/180 – TS pumps, uncouple the seal support flange (17) from the rear flange (19), removing the securing screws (16); the seal o-ring should also be removed together with this (18)

9) remove the screw (9) securing the lantern to the electric motor

10) extract the lantern (7)

11) slacken the dowel (not visible in the image) used to secure the pump shaft to the electric motor shaft and proceed with extraction.

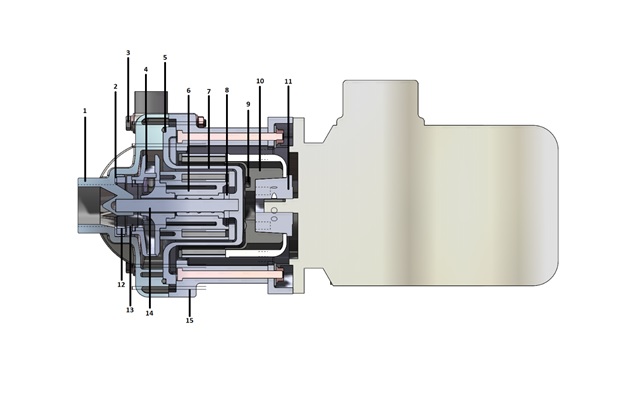

DISMANTLING A HORIZONTAL MB CENTRIFUGAL PUMP WITH LIP SEAL

If you have to dismantle a horizontal MB centrifugal pump with lip seal, you will have to:

1) disconnect the electrical wires entering the electric motor cover

2) disconnect the circuit pump

3) remove the screws (1)

4) uncouple the pump unit (3) and o-ring (7)

5) unscrew the caps (2), making sure you secure the impeller using a soft belt, so as not to damage the paddles

6) extract the impeller (5) from the shaft (14), taking care with the seal o-ring (4 and 6)

7) Extract the ceramic cylinder (10) together with the spacer washer (11)

8a) In the case of MB 80/100 – TL pumps, uncouple the seal support flange (8) from the remaining elements

8b) In the case of MB 110/180 – TL pumps, uncouple the seal support flange (16) from the rear flange (18), removing the securing screws (15); the seal o-ring should also be removed together with this (17)

NB: only extract the lip seal (9) from its seat if it is damaged

9) remove the screw (12) securing the lantern to the electric motor

10) extract the lantern (13)

1) slacken the dowel (not visible in the image) used to secure the pump shaft to the electric motor shaft and proceed with extraction.

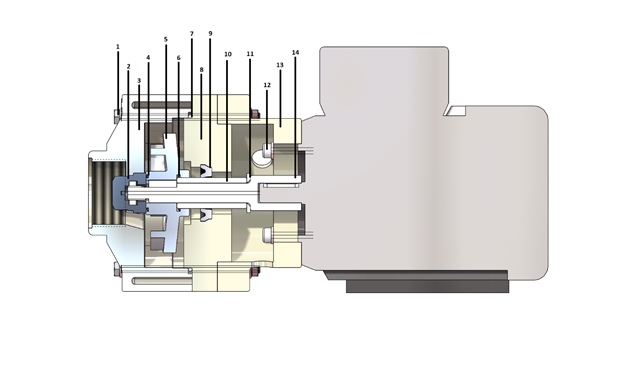

DISMANTLING A MAGNETIC DRIVE DM CENTRIFUGAL PUMP

Lastly, if you have to dismantle a magnetic drive DM centrifugal pump, these are the steps to follow:

1) disconnect the electrical wires entering the electric motor cover

2) disconnect the circuit pump

3) remove the screws (3)

4) uncouple the pump unit (1) and remove the o-ring (5)

(5) only if the thrust bearing ceramic is damaged should it be removed (12) along with the cap (2)

6) remove the whole magnetic unit including the impeller and graphite thrust support ring (13 + 4 + 6), taking care not to damage the ceramic shaft guide (14)

7) if one of the parts is damaged, uncouple the elements 13, 4 and 6

8) remove the ceramic shaft guide (14)

9) extract the ceramic fifth wheel (8)

10) extract the rear unit (7) from its seat. This is the point at which the pumping unit is removed.

11) remove the countersunk screws (9)

12) extract the internal magnetic unit (10)

Next stages, such as the removal of the lantern, compromise the factory centring, so this can only be done by qualified personnel (Debem Srl and its authorised service centres).

CONCLUSIONS

Should you require more detailed instructions concerning “how to dismantle a centrifugal pump”,we recommend consulting the user manual.

For any other queries, please contact our technical office at any time.