Mechanical seals for pumps are elements whose purpose is to separate two environments, between which there must be no fluid communication.

The term mechanical seal precisely denotes a system for containing fluids inside a tank in which a rotating shaft passes through a stationary housing or in which the tank rotates around the shaft. Mechanical seal technology is a combination of mechanical engineering and physical properties.

In particular, the heart of mechanical seal technology is tribology: the science that studies friction, lubrication and wear, i.e. all the problems that can arise in relative motion between interacting surfaces under load.

In the case of pumps, there are different types of mechanical seals. In this article, we will analyze the ones most commonly used in industry.

The Use of O-rings as mechanical seals for centrifugal pumps

The term o-ring defines a ring with a circular cross-section used as a seal. O-rings are designed to be inserted into special housings and compressed during the assembly of two or more parts. The joining of the parts between which the O-ring is placed can be of two types:

- Static: the two elements do not move with respect to each other

- Dynamic: the two elements are moving with respect to each other

O-rings must receive adequate lubrication as protection against friction and the heat produced, and they can be made of a wide range of materials depending on the fluid with which they will come into contact. When designing the bearing surfaces, it is necessary to create finely machined grooves for housing the seals (O-rings), i.e. free of ripples or burrs, and sized according to the detailed manuals available.

Main seals for centrifugal pumps

In this section we will analyze the main types of mechanical seals used in the design and assembly of centrifugal pumps.

Bellows Mechanical Seals

Mechanical bellows seals are a type of mechanical seal in which the elastic element is a bellows. This eliminates the need for a secondary dynamic seal, such as o-rings. The purpose of this mechanical element is to separate the fluid inlet chamber from mechanical elements such as motor, shaft, etc.

Generally, this type of mechanical seal is used in the assembly of centrifugal pumps. A bellows mechanical seal is used above all when the pump moves fluids with solid particles in suspension, allowing their percentage to be minimised. This, in the case of this type of pump, must be contained.

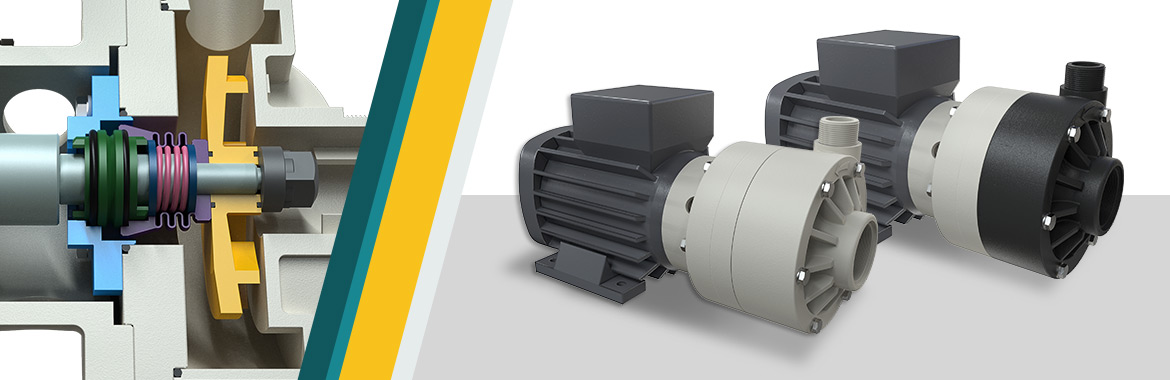

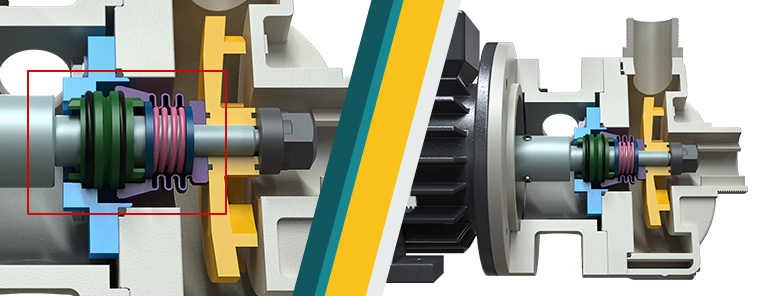

The picture shows a centrifugal pump with a bellows seal manufactured by Debem. The mechanical bellows seal, visible inside the red box, is composed as follows:

- Silicon ring (grey) or other material on request, complete with o-ring (fixed element)

- Ceramic ring (white) or other material on request, complete with o-ring, fixed on the bellows

- Flexible PTFE bellows

- Spring made of AISI 316 stainless steel, which ensures the extension of the bellows and thus a pressure between the two o-rings

The bellows, spring and ceramic ring form a single assembly that rotates in solidarity with the pump shaft, on which the impeller is fixed. The lubrication of the two rings is produced directly by the fluid, which creates a microfilm that reduces rolling friction. The main advantage of using a bellows mechanical seal is that it minimises the risk of seal seizure or shaft wear.

Mechanical Lip Seals

Mechanical lip seals serve to protect moving parts by keeping fluid inside the housing and preventing contamination by dirt or other liquids. The term lip seal is generally used to refer to rotary or radial shaft seals. This type of seal is also often used in the production of centrifugal pumps.

The purpose of this mechanical element is to separate the fluid inlet chamber from mechanical elements such as motor, shaft, etc.

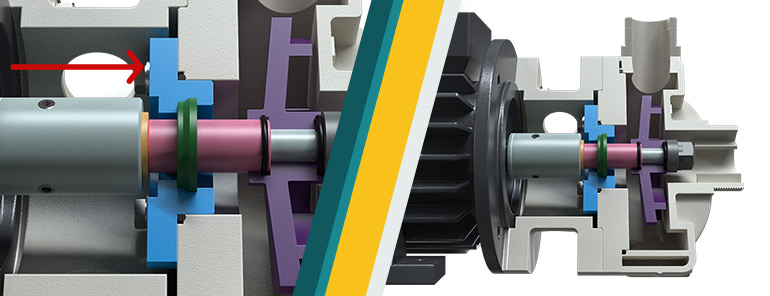

The picture shows a centrifugal pump with a lip seal manufactured by Debem. The lip seal is highlighted by the red arrow. Mechanical lip seals are mainly used in less severe applications than the bellows type. Lip seals can be made of Viton or EPDM, depending on the manufacturer’s requirements.