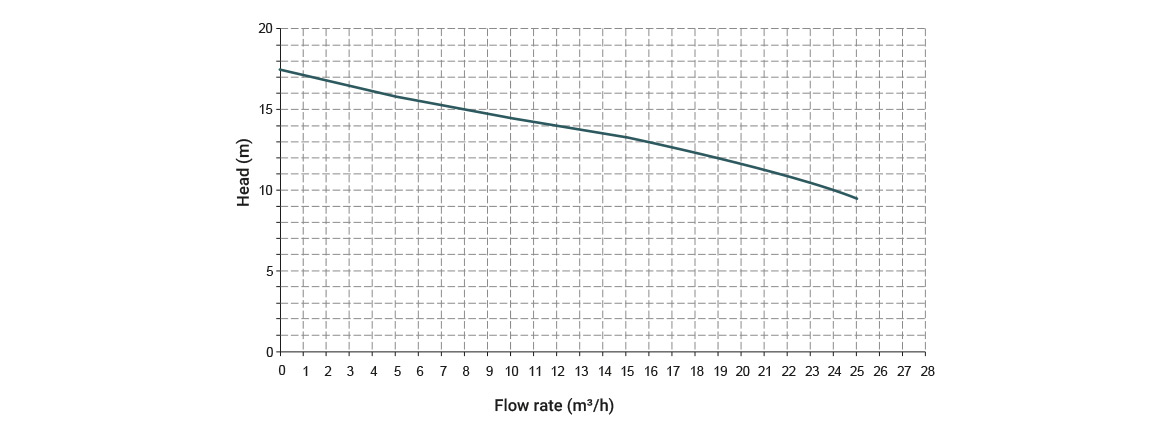

The characteristic curve of a centrifugal pump is a graphical representation of the pump’s ability to move fluids in relation to the pressure level existing during pump operation. The graph represents the interaction of the two variables that describe the behaviour of a pump:

- Head of a pump: defined as the pressure difference between the outlet and the inlet of the pump, expressed in units of height (e.g. in meters).

- Flow rate: the amount of fluid flowing through a section in a certain period.

The curve is fundamental to the selection and sizing of a pump as it highlights the points of maximum efficiency and provides information on the actual ability to meet the requirements of the application system within which it is to be used.

The head of a pump

The head of a pump is defined as the pressure difference between the pump outlet and pump inlet, expressed in units of height (e.g. in meters). The unit of measurement of the head is represented by the symbol m. The head indicates the maximum lift height that the pump can transmit to the pumped fluid. It is a very important factor that determines the pump’s ability to overcome resistances such as bends, valves and pipes. The head of a pump is a key figure in the selection of the most suitable pump for certain structural conditions such as the length and diameter of the pipe, the lifting height or the amount of fluid to be moved.

The flow rate of a pump

The flow rate of a centrifugal pump is the amount of fluid that the pump can move in a given time interval. In other words, it represents the amount of fluid that is pumped through the pump in a unit of time, usually expressed in liters per minute or cubic meters per hour. The flow rate depends on the size of the pump, the rotation speed of the pump shaft and the characteristics of the fluid being pumped, such as density and viscosity. The flow rate is one of the most important technical specifications of a centrifugal pump, as it directly influences its ability to deliver the liquid flow required by the system in which it is installed.

Pump characteristic curve on the Cartesian plane

The representation of a pump characteristic curve on the Cartesian plane shows the flow rate Q on the x-axis and the head H on the y-axis as shown in the graph below:

The characteristic curve represents the ability of a pump to generate fluid flow (flow rate) based on the head. The link between flow rate and head, at constant speed, is typical for each pump. Two other graphs can be used to supplement the information required to analyse a pump: the efficiency curve and the power consumption curve.

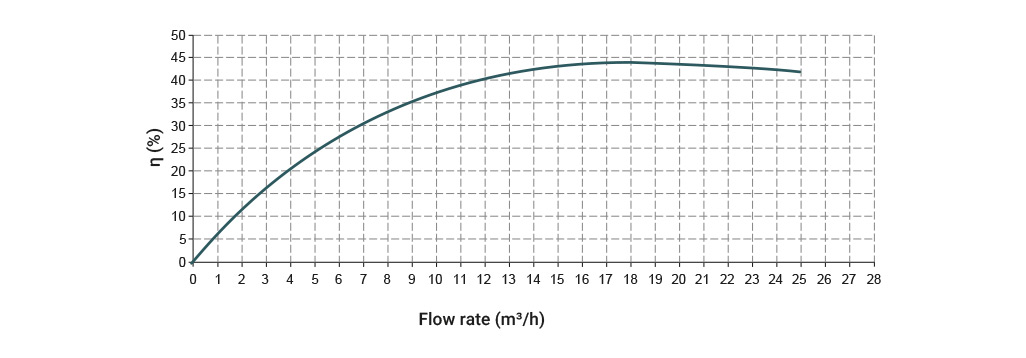

The efficiency curve of a pump

The efficiency curve makes it possible to assess the efficiency of a pump’s operation. The curve represents, on the y-axis, the ratio between pump power and absorbed power (defined by the variable η = Wu/W) in relation to the volumetric flow rate represented on the x-axis by the variable Q. An example of an efficiency curve is shown in the graph below:

The efficiency curve has a bell-shaped pattern: at the point of maximum efficiency, the pump’s operation is optimal.

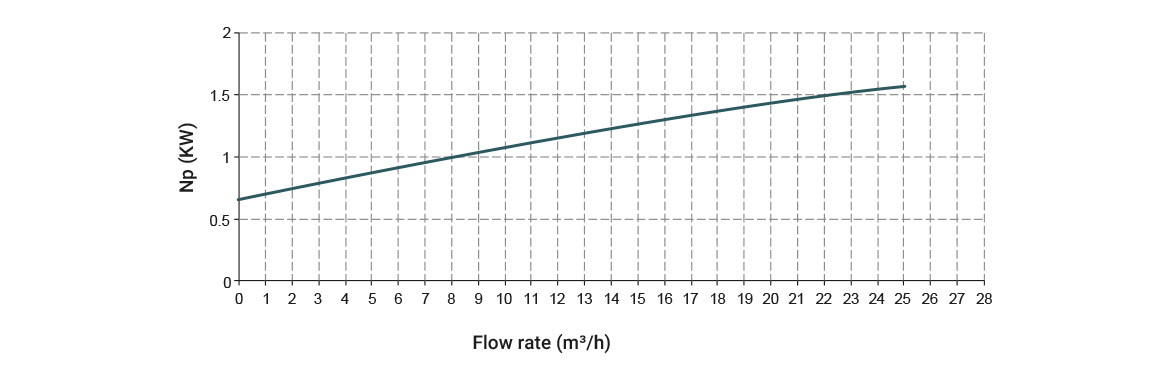

The power consumption curve of a pump

The power consumption curve of a pump is a parameter for assessing the efficiency of a pump. The curve represents, on the y-axis, the electrical power input characterised by the variable W in relation to the flow rate expressed by the variable Q on the x-axis. The power W is the product of the flow rate Q for the head H and the density d of the fluid (W=Q∙d∙H). An example of an absorbed power curve is shown in the graph below:

The absorbed power curve has an upward trend: power increases as the flow rate increases.

Why pay attention to the characteristic curves of a pump?

The characteristic curve of a centrifugal pump clearly expresses the suitability of a specific pump for use within a specific system. The centrifugal pump is a mechanical element driven by an electric motor, and each characteristic curve of the pump refers to a precise rotation of the motor, dependent, in the case of common asynchronous motors, on the supply frequency and the number of poles of the motor itself (e.g. 50 hertz, 2-pole motor: 2900 rpm).

On some models of centrifugal pumps it is also possible to find indications regarding the NPSH, i.e. the maximum admissible suction height before incurring cavitation phenomena, which are destructive for the mechanical parts of the pump.

For any further information on the characteristic curves of Debem pumps, please contact the technical sales team, who will support you in analyzing the best solution for your operating environment.