The pump power, also known as absorbed power, represents the energy imparted to the pumped fluid to increase its speed and pressure. All hydraulic pumps, to move and increase the pressure of a fluid, consume power. The power required by the pump depends on several factors’ ancillary to the pump itself, including the efficiency of the pump motor and the pressure. Additional factors affecting pump power refer to the density, viscosity, and flow characteristics of the fluid being transported. This article provides a range of information useful in understanding the required power of a pump and delves into the different methodologies for calculating the “pump power” factor.

Factors affecting the pump power

Pumps are not able to transfer all the energy they receive; due to friction, dissipation, turbulence; so the energy absorbed in the unit of time by the motor, called absorbed power, will be greater than that actually acquired by the liquid. The ratio of the useful power to the absorbed power defines the efficiency of the pump. The total efficiency of a pump considers the pressure losses inside the machine. These losses are of three types, specifically:

- HYDRAULIC

- VOLUMETRIC

- MECHANICAL

Hydraulic power losses:

Hydraulic losses are due to the decrease in energy due to shock and friction of the moving liquid inside the pump.

Volumetric power losses:

Volumetric losses are due to the flow rate of liquid that, although “worked” by the pump, is not conveyed into the discharge line, OUTPUT FLOW, because:

- of the clearances between the moving and fixed organ.

- of the delay in the closing of the valves.

- of the perfect tightness of the seals.

- Of the presence of gases and vapors being released at the inlet due to suction depression and/or temperature for hot liquids.

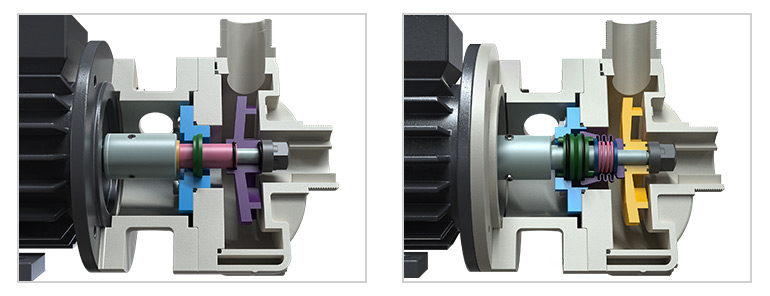

Mechanical power losses:

Mechanical losses are due to friction and mechanical resistance in general and mainly to ball bearings.

To define the pump power rating we must introduce certain necessary parameters.

Pump performance

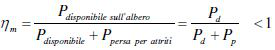

Mechanical pump performance

This value takes into account the friction between the mechanical parts of the pump.

Usually it has values between 0.88 and 0.96, which are rather high. After all the reduction of friction is one of the key targets to safeguard the life and reliability of the pump.

Electric pump performance

This value represents the efficiency of the electric motor, usually around 0.9.

Volumetric pump performance

The volumetric performance of a pump is used to quantify the losses of fluid volume due to the play between pump impeller and casing. The values are usually between 0.9 and 0.96.

Calculating pump power rating

Once these values are defined the total efficiency of the pump will be given by the result of the various efficiencies:

ηt = ηm * ηel * ηvol

Now we can calculate the power of the pump.

Theoretically the power is defined as the work that the machine must perform to move a mass of fluid in the unit of time.

The formula for the power of a pump is:

![]()

L = work (joule)

g = gravity acceleration (m/s2)

ρ = fluid density (kg/dm3)

t = time (s)

Hm = overall losses from the plant (m)

M = mass (kg)

Qm = volumetric load (m3/s)

The resulting power is expressed in watt (or in kilowatt, where 1 kW = 1000 W).

In order to take into account the various losses, the power must be divided by the total efficiency.

Choosing a pump with the appropriate power

As we have seen, making the power calculation for a centrifugal pump is quite simple. By knowing the different characteristics and applying the formulas given in this article, it is possible to correctly identify the necessary values. However, choosing a pump with the appropriate and necessary power for the specific application needs can be more complicated. In this case, our team can offer personalized advice on the Debem centrifugal pump catalog to properly support the selection and purchasing processes.