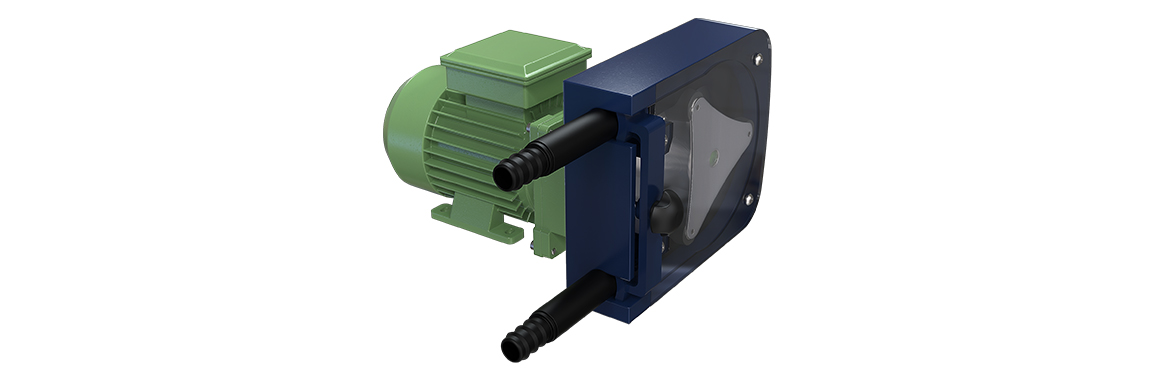

Peristaltic pumps are volumetric pumps that operate on the basis of the peristalsis principle, which applies pressure to the fluid with an occlusion that runs along the hose. They consist of a rotor on which 2 or more rollers or pads rotate, a flexible elastic hose and an electric motor.

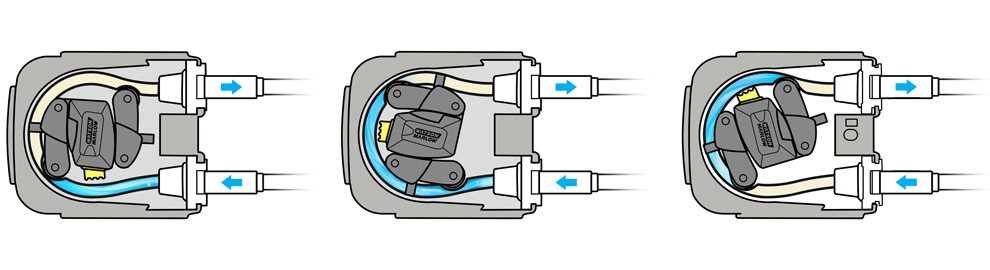

The images below show a peristaltic pump with rollers.

The first roller rolls against the hose, compressing it. This creates a vacuum that sucks (image 1) and pulls (image 2) the fluid.

When the fluid reaches the delivery (image 3), the second roller restarts the process.

HOSE

This is the only part of the pump that comes into contact with the fluid and therefore it must be chemically compatible with the fluid as well as mechanically resistant to the rubbing and squeezing action.

The fundamental characteristic of the hose is its elasticity, which allows the hose to be deformed and to return to its original shape, because it ensures its long life and recreates the suction conditions.

The hose is usually made of silicone and/or PVC materials.

ROLLERS

These are the mechanical elements that press the fluid.

There may be 2 to maximise the flow rate, or more, to minimise the pulsation of the fluid pumped, at the expense of flow rate.

USES OF PERISTALTIC PUMPS

Peristaltic pumps are used in processes that require that the fluid does not come into contact with the pump (dangerous fluids that must not be contaminated, etc.) or in applications with highly viscous fluids or with a great deal of suspended solids, which are therefore difficult to move.

This type of pump allows the flow rate to be calibrated, which renders it suitable for dosing processes, as gear motors can be applied to select the number of RPMs.

Advantages:

- Self-priming

- Suitable for viscous fluids rich in suspended solids

- Suitable for dosing

- Dry running without failures