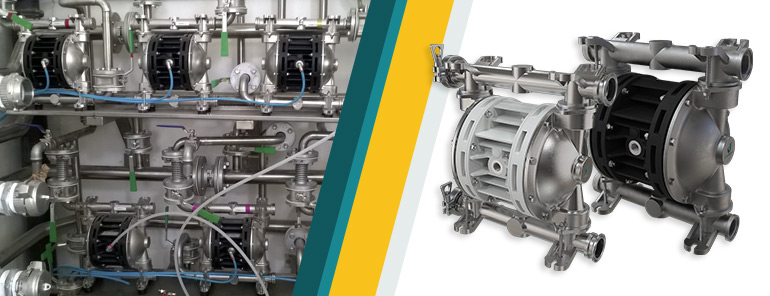

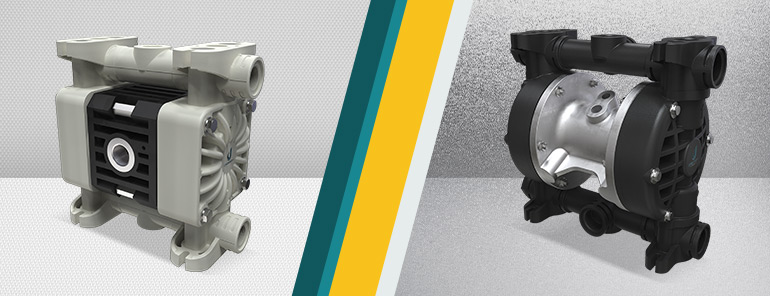

Air Operated Double diaphragm pumps are reliable and versatile tools widely used in various industrial sectors for transferring liquids with high viscosity or containing solid elements. Due to their simple and functional design, as well as their ease of use, they have become one of the preferred solutions for various transfer applications. However, like any other mechanical device, they can encounter certain issues during installation and usage.

Table of contents

- Pressure and Size of Air Line

- Diaphragm Breakage

- Defective Gaskets

- Tubing Size

- Freezing Issues

- Bolt Tightening

- Speed and Priming

- Check Valve Failures

- Fluid Line Restrictions

- Material Corrosion

To ensure optimal performance and maximize the lifespan of your double diaphragm pump, it is fundamental to be aware of common problems and their corresponding solutions. In this article, we will guide you through the necessary steps to resolve the most frequent issues and ensure the proper functioning of your pump.

1. Checking Air Pressure and Line Size

When installing a double-diaphragm pump, the pressure and the size of the air line are two key factors to consider.

Problem: The inlet air pressure must be adequate to ensure proper pump operation. Insufficient air pressure could affect pump performance by reducing the flow rate and pressure delivered. Conversely, excessive pressure could cause excessive stress on the diaphragms and pump components, reducing their life and increasing the risk of failure.

Solution: To ensure optimal operation, it is necessary to check the manufacturer’s recommended air line size and ensure that the inlet air pressure is higher than that required by the pump. This, ensures optimal air flow and avoids restrictions that could affect the performance of the diaphragm pump.

2. Preventing Diaphragm Breakage in AODD Pumps

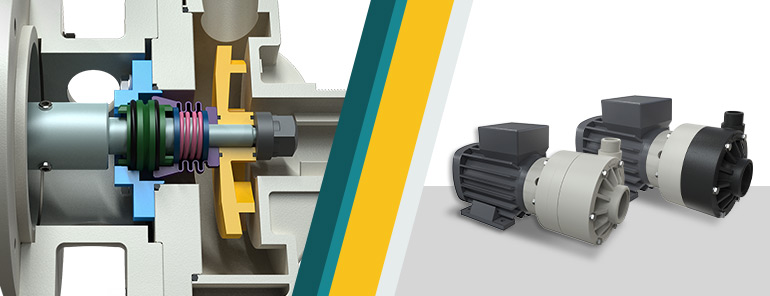

Diaphragm material and manufacturing method are key factors that affect the service life of a diaphragm pump. The choice of diaphragm material is critical because it must be able to withstand the mechanical, chemical and thermal stresses to which it is subjected during pump operation. Each material has its own mechanical and chemical resistance characteristics and operating temperature limits. The diaphragm manufacturing method is also an important factor to consider. The quality of workmanship and accuracy in the manufacture of the diaphragm can affect its durability and performance. A careful manufacturing process can ensure better structural integrity of the diaphragm and greater resistance to mechanical stresses.

Problem: One of the most common problems associated with AODD pumps concerns the diaphragm. This key pump component is often subjected to high levels of mechanical stress during its operation. Over time, these stresses can cause cracking and damage to the diaphragm itself. One contributing factor to this problem is the operating pressure of the pump. When the inlet air pressure is too high, the diaphragm is subjected to increased stress during each pump operating cycle. This additional stress can accelerate diaphragm wear, leading to shorter service life and potential failure. In addition, the number of strokes made by the pump is another critical factor. Pumps operating at higher speeds perform a greater number of strokes during a given period of time. This means that the diaphragm is subjected to greater stress over its operating life. As a result, high-speed pumps tend to have a shorter diaphragm life than pumps operating at lower speeds.

Solution: To prevent diaphragm breakage, it is advisable to consider several aspects. Firstly, ensure the use of high-quality diaphragms made from suitable materials for the working conditions and produced according to reliable manufacturing standards. Secondly, carefully monitor and adjust the working pressure of the pump to avoid subjecting the diaphragm to excessive stress. It is important to refer to the manufacturer’s specifications to determine the recommended operating pressure for the diaphragm. Finally, evaluate the pump’s operating speed, striving to balance production needs with diaphragm longevity. Reducing the operating speed can contribute to a longer diaphragm lifespan.

Regular inspections of the diaphragm are advisable to identify any signs of wear or early damage. In case of diaphragm rupture or deterioration, prompt replacement is necessary to prevent leaks or pump malfunctions. Follow the manufacturer’s recommendations for maintenance and diaphragm replacement, considering the specific stress factors for the pump’s application.

3. Avoiding Leakage Due to Defective Gaskets

Double diaphragm pumps are widely used devices for liquid transfer in various industrial sectors. However, one common problem that can occur with these pumps is leakage, which can have a range of undesirable consequences.

Problem: Leakage caused by defective gaskets can reduce the pump’s efficiency and performance, leading to liquid waste and potential environmental damage. To prevent leaks, it is crucial to pay attention to the gaskets used in the pump.

Solution: During membrane pump installation and maintenance, it is important to ensure that all gaskets are properly tightened according to the manufacturer’s specifications. Gaskets should be correctly positioned and tightened to ensure a tight seal. Loose or damaged gaskets can result in leaks. By using properly installed PTFE gaskets and replacing them regularly, the risk of unwanted leaks can be drastically reduced. A leak-free pump will operate efficiently, reducing liquid waste and ensuring reliable transfer.

4. Verifying the Correct Size of AODD Pump Tubing

Ensuring the correct size of tubing is essential for the proper functioning of the double diaphragm pump. It is important to verify that the dimensions of the inlet and outlet tubing align with the manufacturer’s recommendations. Using tubing with incorrect dimensions can lead to a range of problems that may require costly repairs and maintenance.

Problem: When the tubing is improperly sized, the phenomenon of cavitation can occur. When the pump operates at a high flow rate, but the diameter of the tubing is too small, the fluid velocity increases significantly, reducing the pressure inside the tubing. If the pressure drops below the vapor pressure of the fluid, vapor bubbles form and then violently collapse when the fluid returns to a higher pressure, generating shockwaves inside the pump. Cavitation can cause mechanical damage to internal components of the pump, such as the diaphragm, valves, and compression chambers. Additionally, it reduces pump efficiency as the vapor bubbles occupy space within the pump, reducing the fluid transfer capacity.

Solutions: To prevent cavitation issues, it is crucial to follow the manufacturer’s recommendations regarding tubing size. Ensure that the dimensions of the inlet and outlet tubing match the specifications indicated by the pump. Using flexible connections can also help absorb vibrations caused by pump operation, thereby reducing stress on the tubing and preventing damage or malfunction. Paying attention to the correct sizing of tubing will not only contribute to the proper functioning of the pump but also help prevent future issues and maximize system efficiency. Following the manufacturer’s recommendations and using appropriate flexible connections are important steps to avoid costly repairs and ensure the long-term proper operation of the double diaphragm pump.

5. Avoiding Membrane Pump Freezing Issues

During the operation of membrane pumps, high temperatures are generated due to fluid friction and compression. In highly humid operational environments or during low atmospheric temperatures, the elevated operating temperature can lead to freezing issues within the pump, compromising its proper functioning.

Problem: If erratic pump operation, such as decreased performance or unstable flow, or the presence of ice on the muffler is observed, it is likely that there is a freezing problem inside the pump. Freezing can occur due to the high temperatures generated during pump operation, especially in humid environments or at low temperatures. When the ambient temperature drops below the freezing point of the fluid, the water contained in the system can solidify and form ice. This can obstruct the fluid flow, reducing the transfer capacity and compromising the pump’s performance. Freezing can cause damage to internal components of the pump, such as the diaphragm and valves, compromising their functionality. Additionally, the collapse of ice bubbles during the thawing process can generate small explosions or shocks inside the pump, causing further damage and reducing its lifespan.

Solution: To address this issue, there are several solutions that can be adopted. Firstly, it is advisable to reduce the incoming air pressure to the pump. By reducing the pressure, the overheating generated during operation is also reduced, thereby lowering the risk of freezing. This operation can be performed by adjusting the compressor setting or using a pressure regulator. Secondly, increasing the size of the pump can be considered. By increasing the pump size, the operating speed and heat generation are reduced. This mitigates the risk of overheating and fluid freezing. Thirdly, installing an air discharge system to a remote location is an option. This allows the heat and moisture generated during pump operation to be expelled, reducing the risk of freezing. Additionally, using an air filter with a water collection device is recommended. This helps trap moisture present in the supply air, preventing ice formation within the pump. The use of an air heater to maintain the temperature above freezing can also be considered.

Taking preventive measures to avoid freezing is crucial to ensure the proper functioning and longevity of the double diaphragm pump. Carefully monitoring pump operation and implementing appropriate precautions can help prevent costly damages and unexpected production disruptions.

6. Checking Proper Bolt Tightening

Over time, the bolts used during the assembly of AODD pumps to hold the various components together may relax due to the intense forces generated by possible operating vibrations.

Problem: Bolt loosening can reduce the pressure on the sealing surfaces of the pump, causing unwanted leaks. This issue is particularly common in plastic pumps, as the softer material and plastic molded surfaces can deform due to internal stresses. Leaks can negatively impact pump performance by reducing efficiency and causing liquid waste.

Solution: To prevent leaks due to bolt loosening, it is important to take preventive measures. One recommended practice is periodic bolt tightening to ensure that the sealing surfaces remain properly sealed. This can be done using a torque wrench to apply the correct tightening torque to the bolts. In the case of softer plastic pumps, it may be advisable to use reinforcing metal plates. These plates, strategically positioned, provide additional support to the plastic sealing surfaces, reducing the risk of deformation and improving the seal. These precautions contribute to maintaining pump efficiency, reducing liquid waste, and ensuring reliable long-term operation.

7. Reducing Speed for Proper Pump AODD Priming

Double diaphragm pumps are devices designed to create a low-pressure zone within the suction chambers to effectively draw in the fluid. This versatile and reliable design makes them a preferred choice in many industrial sectors for liquid transfer. However, for double diaphragm pumps to function correctly, it is crucial to pay attention to several factors, including air pressure and line size.

Problem: One of the issues that can arise during the use of double diaphragm pumps is related to the incoming air pressure. If the air pressure is too high, the pump doesn’t have enough time to prime properly. This can compromise the effectiveness of the suction process and limit the pump’s ability to transfer the fluid completely and efficiently. Excessive incoming air pressure can cause a rapid pressure change within the suction chambers, reducing the available time for fluid intake. As a result, the pump may not be able to draw in an optimal amount of liquid, affecting the overall system performance.

Solution: To address this issue, it is advisable to reduce the pump’s speed using the air regulator. By adjusting the operating speed of the pump, a more favorable environment for priming the suction chambers is created. Lowering the speed helps avoid a rapid pressure change that could impede the pump’s suction capability. Additionally, this adjustment allows for better control of the priming process, ensuring that the fluid is properly drawn in before the pump increases its operating speed. Another option is to adjust the pump’s speed while maintaining a constant operating pressure using a needle valve placed at the air inlet of the pump.

8. Avoiding Check Valve Failures

Check valves play a crucial role in double diaphragm pumps by allowing one-way flow of the fluid and preventing backflow. However, these valves are susceptible to failures that can compromise the efficiency and overall performance of the pump.

Problem: One common issue that can occur in AODD pumps is check valve failure. These failures can be caused by objects or debris obstructing the valve ball and its seat, preventing a proper tight seal. When this happens, fluid leakage occurs, which can affect the proper functioning of the pump. Additionally, wear and tear on the valve ball and seat can create additional leak paths. This wear can be caused by the presence of abrasive particles in the liquid or by using materials that are not suitable for the valve balls and seats.

Solution: To avoid check valve failures, it is advisable to take preventive measures. Firstly, using a filter is recommended to reduce the chance of unwanted objects obstructing the valve ball and seat. This filter will trap debris before it reaches the check valves, reducing the risk of failures. Additionally, regular pump flushing should be performed to remove any accumulated debris on the check valves. This rinsing operation can help clear the valves from any obstructions and ensure proper functioning. Finally, it is important to regularly inspect the check valves’ condition and replace them if necessary. Wear and tear on the valve ball and seat can compromise the valve’s sealing capability, so timely replacement is crucial to ensure the proper functioning of the double diaphragm pump.

9. Removing Restrictions in the Fluid Line

AODD pumps are widely used in various industries for efficient and reliable liquid transfer. However, during installation and use of these pumps, it is crucial to pay attention to potential issues that may arise, such as restrictions in the fluid line.

Problem: One common problem that can occur in double diaphragm pumps is the presence of restrictions in the fluid line. Restrictions can impede the flow of the liquid and reduce the pump’s efficiency. This can be caused by partially closed valves, obstructions, or bends in the fluid line. Additionally, vibrations or abnormal noises during operation may indicate the presence of restrictions or issues with the piping.

Solution: To address this problem, it is essential to carefully inspect the fluid line. Check that the valves are fully open and that there are no obstructions or bends in the line. Pay attention to any unusual vibrations or noises during operation as they may indicate restrictions or problems in the piping. If restrictions are detected, prompt action should be taken to remove them and restore the fluid flow.

10. Controlling Material Corrosion

Proper management of corrosion and abrasion is essential to ensure the correct operation and longevity of AODD pumps. Corrosive or abrasive fluids can cause damage to the pump’s internal surfaces, including the diaphragms and valves. Therefore, it is important to take preventive measures to protect the pump from these issues.

Problem: Exposure to corrosive or abrasive fluids can cause damage to the pump’s internal surfaces. Corrosion can erode the metal surfaces, reducing the pump’s efficiency and causing leaks. Similarly, abrasive particles can cause premature wear on the components, compromising the pump’s performance and lifespan.

Solution: Several solutions are available to properly manage corrosion and abrasion. Firstly, it is advisable to use corrosion and abrasion-resistant materials for parts exposed to aggressive fluids. Materials such as stainless steel, reinforced polyethylene, or other chemical-resistant polymers can provide increased protection to the pump’s internal surfaces. Additionally, applying PTFE coating membranes can protect thermoplastic diaphragms, or in cases of high abrasion, opting for robust fabric-reinforced rubber diaphragms. Debem pumps can be configured appropriately when handling abrasive fluids.

In addition to using appropriate materials and coatings, it is recommended to carefully monitor the fluids being pumped and prevent exposure of the pump to corrosive or abrasive substances whenever possible. Proper material selection, using a chemical compatibility software, and adopting preventive maintenance practices can help preserve the integrity of the pump and prevent damage caused by corrosion and abrasion.

To increase the lifespan of the air operated double diaphragm pumps…

In conclusion, by carefully following these steps, it will be possible to effectively address the most common issues associated with the use of double diaphragm pumps. Debem, a leader in the manufacturing and distribution of double diaphragm pumps, provides comprehensive technical documentation necessary to manage the main usage and maintenance challenges.

For complete support and professional consultation on double diaphragm pumps, we encourage you to contact the Debem sales team. Don’t hesitate to leverage their expertise and present your specific needs to receive the best solution for your application. Contacting Debem is the first step towards ensuring the proper operation and maximum efficiency of double diaphragm pumps.