A pulsation damper is an equipment capable of playing a very important role in the use of double diaphragm pumps. As can be seen from the name, this accessory is aimed at reducing pulsations and vibrations during pump operation, thus ensuring a “continuous” and precisely non-pulsed flow rate and a reduction of vibrations on the system pipes.

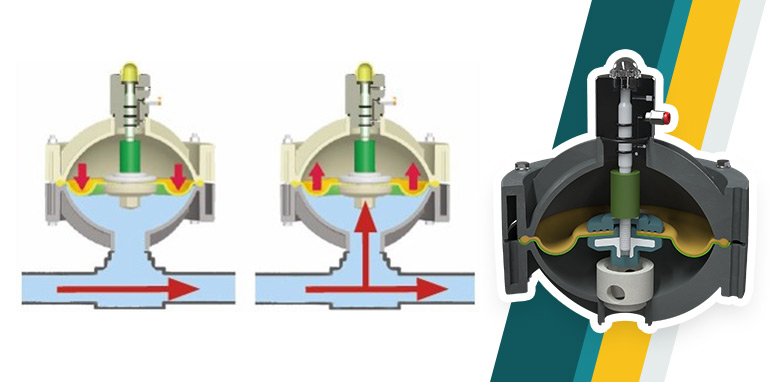

How does a pulsation damper work?

A pulsation damper works thanks to the same compressed air that feeds the pump. The compressed air introduced into the counter-pressure chamber behind the membrane creates a pneumatic damping cushion that self-adjusts according to the stress exerted by the pressure pulse of the fluid generated by the pump.

EQUAFLUX dampers are used with fluids of high apparent viscosity even in the presence of solid parts in suspension. They automatically adapt to the system conditions, without manual adjustment or calibration. The high ability to minimize pulsations, vibrations and water hammers makes this component a suitable equipment for safeguarding the system, giving regularity to the outgoing flow. The wide choice of construction materials allows you to determine the best chemical compatibility with the fluid and / or the environment without neglecting the correct temperature range. The dampers are also available for use in a potentially explosive environment (ATEX certification).

Risks deriving from fluid pulsations

Inside the hydraulic systems, the pulsations of the fluid can cause phenomena called water hammer consisting of pressure peaks caused by a sudden change in the flow rate inside the pipes or by the sudden closure of a valve. The effects of water hammer vary according to the size of the pipeline and the speed and density of the fluid but can often cause extensive damage to the elements of a system. To preserve the system from water hammer and vibrations, it is possible to use the pulsation dampers of the Equaflux series that can automatically adapt to the operating conditions of the pump.

Application contexts of pulsation dampers

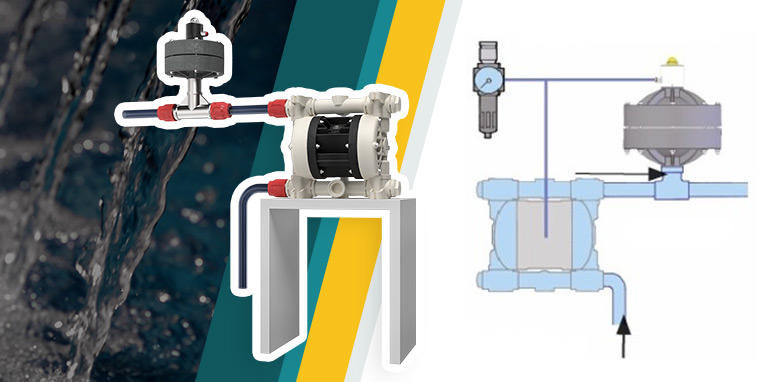

Equaflux pulsation dampers are normally applied to pneumatic double diaphragm pumps. The latter, during the phases of use, can record pressure peaks which, if not controlled, can damage the elements of a system. The main benefits associated with the use of pulsation dampers can be summarized in the following points.

- Minimize or eliminate pulsations to the advantage of the equipment downstream of the system.

- Protect the welds and pipe supports and system components from damage due to pressure.

- Considerably limit pump vibrations thus ensuring better efficiency performance.

- Reduce the effects of loading on the pump.

- Preserve the efficiency and duration of any filters.

- Reduce noise pollution resulting from pump operation.

The application of diaphragm pumps equipped with pulsation dampers refer to the entire process industry: hydraulic systems, use in chemical transformation processes, use within the petrochemical, mining sectors and much more. The EQUAFLUX series is also available with ATEX certification and therefore can be used directly within sectors with the presence of explosive risks.

Conclusions

Pulsation dampers are very versatile tools whose use can vary according to the needs of the operating processes and application sectors. For this reason, a sales team is at your disposal to support you in choosing the most suitable configuration for your needs. Contact the Debem team now.