A very common question asked by users of pneumatic double diaphragm pumps (AODD) is the following: what is the maximum viscosity of a fluid that can be transferred inside the pump?

The answer is more about the piping system to which the pump is connected than the technical characteristics of the pump itself. However, some techniques can be employed to estimate the factors affecting flow rates in diaphragm pumping systems with high viscosity fluids. The questions that need to be answered to determine if an application meets the requirements needed to handle high viscosity fluids are as follows.

1. Can the AODD pump draw fluid at the desired flow rate?

The answer to this question can be found by comparing the dry lifting capacity of the pump with the loss of the suction line. It is therefore necessary to assess whether the dry lifting capacity of the pump exceeds the loss of the suction line at the desired flow rate.

To determine if the pump can suck the fluid to be processed, it is necessary to calculate the suction line loss for the desired flow rate. The diameter of the pipe and the flow rate greatly affect the loss of the line. Often it is necessary to increase the diameter of the suction line to compensate for the loss. Indeed, an AODD pump cannot operate in systems where the loss of the suction line exceeds the pump capacity. To meet the desired flow rate, the diameter of the suction line must be increased to reduce the loss of the suction line within the operating capabilities of the AODD pump.

2. Can the AODD pump exceed the total dynamic head of the system?

If the inlet air pressure exceeds the dynamic head of the systems, then fluid can be transferred into the pump system. For the longevity of the AODD pump, the systems should operate within the average range of the pump capacity.

To calculate the dynamic head of the system it is necessary to determine the total static head and the line loss due to friction. If the frictional loss due to a line exceeds the maximum operating pressure of the pump it is necessary to increase the diameter of the discharge line to reduce the losses to a level within the operating range of the AODD pump.

The choice of the pump based on the characteristics of the system

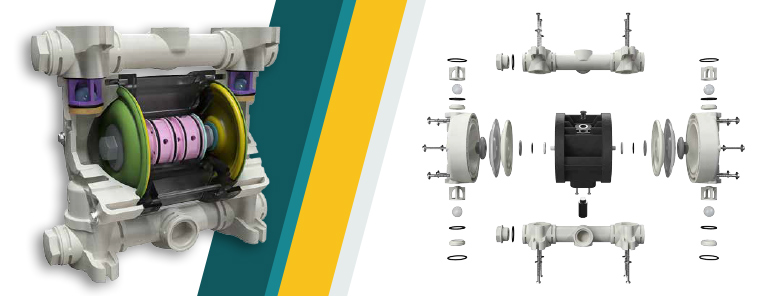

Debem makes available for each product the documentation that includes the viscosity correction curves. These summarize the frictional losses that occur when a viscous fluid passes through the pump.

After considering the loss of the suction line and the dynamic head of the system, it is necessary to consider the losses that occur during the passage of the fluid inside the pump. The viscosity correction curves can be an aid in this sense since they clearly show the decrease in pump capacity based on the increase in the viscosity of the fluid. The choice of the pump must therefore consider the type of flow transported, its viscosity and friction losses within the system.

Conclusions

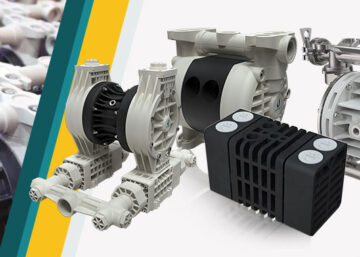

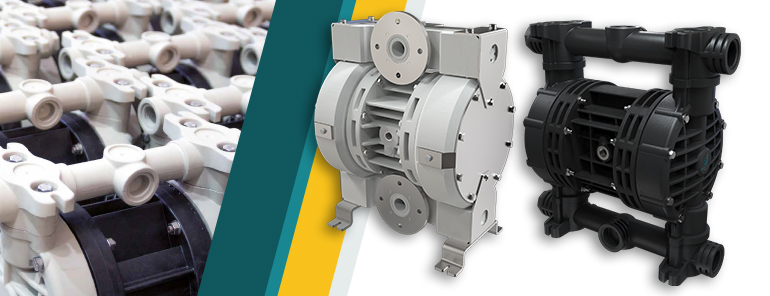

Debem designs and manufactures double diaphragm pneumatic pumps suitable to satisfy any operational and environmental need. Within the section dedicated to technical data sheets, we provide all the information and data relating to the performance of the pumps produced to facilitate the choice of the most suitable one for the target plant in terms of chemical compatibility and fluid viscosity. Configure the pump that best suits your needs or contact our Customer Service for more information.