In recent years, the sewage pumps sector has undergone significant evolution, mainly driven by the trend of numerous companies towards reducing and recovering liquid waste generated by their production processes. Air-operated double diaphragm (AODD) pumps are an essential tool in processes aimed at purifying water contaminated by industrial activities, in sludge treatment, in the filtration of waste products, and in the separation of solids from liquids.

The different types of water treatment plants.

To fully understand the crucial role of double membrane pumps within the industry, it is useful to make a distinction of the different wastewater treatment processes. Wastewater treatment plants ensure that polluted water, from industrial activities such as oil refineries, chemical and petrochemical plants, is processed within the pollution levels required for discharge to sewers, waterways, lakes and oceans. There are currently four types of water treatment plants.

- Wastewater treatment plants that remove harmful pollutants from wastewater prior to its release into the environment.

- Activated sludge plants that use activated sludge to degrade biological pollutants in wastewater. This process involves prolonged oxygenation of wastewater to allow biological components to dispose of most organic debris and pollutants.

- Effluent treatment plants used to treat wastewater in sectors with high contaminant risk, such as pharmaceutical manufacturing and chemical industries.

- Common and combined effluent treatment plants that treat a combination of wastewater from different sources, combining various treatment methods to handle a wide range of pollutants.

All of these plant categories ensure that the water, once processed, is suitable either for release to the environment or for reuse.

The role of diaphragm pumps in the water treatment industry

Due to their ability to handle a wide range of materials, including solid wastes, high-viscosity liquids, and abrasives, double-diaphragm pumps are ideally suited to the following stages of wastewater treatment.

- In industrial wastewater treatment involving the transfer of hazardous liquids, diaphragm pumps provide safe and efficient handling by injecting acidic or antimicrobial substances.

- In filtration processes, AODD pumps, with their robust construction configuration and low maintenance requirements, are used in filter presses to separate solid and liquid elements.

- In effluent treatment, diaphragm pumps are used for the neutralization and management of chemical spills and for the removal of debris and foam. These pumps facilitate the extraction of settled material and the management of debris floating on the surface, effectively contributing to the purification process.

- In sludge removal processes, double membrane pumps are used to handle a variety of materials, including thickened sludge, clarified sludge, or organic waste. Their ability to safely remove toxic chemicals without risk to operators makes them a reliable and efficient solution.

Debem’s wastewater pumps.

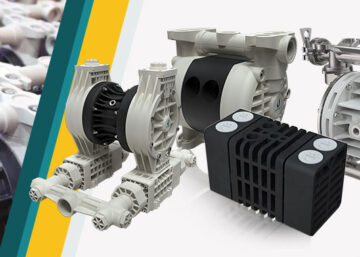

Debem stands out for its 30 years of experience in the design of double-diaphragm pumps (AODDs) suited to meet the demanding needs of the water treatment industry. Debem’s water treatment pumps, thanks to a selection of materials that ensure total compatibility with all pH values, are designed to handle strongly acidic or highly basic fluids. This versatility makes them ideal for tackling different water treatment challenges.

A distinctive aspect of Debem diaphragm pumps is their ability to handle fluids with high density or viscosity. Their operating principle and specific design features allow for the effective management of complex fluids with suspended solid elements.

Debem sewage pumps, thanks to the use of special anti-abrasion materials, reinforced membranes, and self-lubricating plastics, are highly effective in the treatment of abrasive sludges, thus ensuring optimal operation and longevity, even in the management of the most critical processes.

Finally, Debem wastewater pumps are also designed to cope with emptying wells or tanks with negative head. “Long-Life” diaphragms, an exclusive feature of Debem products, ensure a longer service life than those of competitors, even under extreme working conditions.

In conclusion, Debem’s AODD pumps demonstrate the company’s ability to effectively meet the needs of a very complex and variable sector. To discover the solution that best suits your specific needs, we invite you to contact our sales team, ready to provide you with assistance and personalized advice.