Introduction

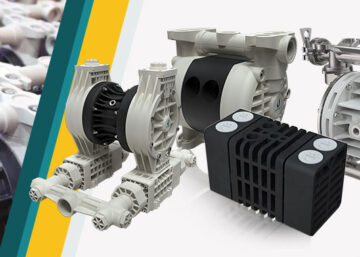

Thanks to the high conditions of reliability and versatility, AODD pumps can be used in numerous application sectors without the need for costly installation operations or sizing calculations.

One of the strengths of AODD pumps is the reduced need for maintenance, compared to other technologies, which minimizes downtime and production interruptions. For this reason, double diaphragm pumps represent a valid solution for extractive production processes, increasing their efficiency and safety.

Typology of the Extractive Sectors

Before discovering how to use diaphragm pumps in the mining sector, we define what is meant by the mining sector. The mining and quarrying sector includes all processes aimed at extracting valuable resources from the earth, specifically non-renewable resources: fossil fuels, minerals, water and precious metals. There are four methods of mining that differ mainly in the type and location of the deposit to be extracted. Each of these methods involves different levels of safety and environmental impact. In particular:

- Underground extraction: identifies the excavation and construction of tunnels and galleries aimed at reaching and recovering the resource deposit located in depth on the surface.

- Surface extraction: describes the activities of removing the bedrock to access the resource deposit which in this case is in a superficial position.

- “Placer” extraction: carried out in riverbeds or sedimentary environments and aimed at sieving precious metals (eg gold). Operations include the extraction and rinsing of the sedimentary material to extract the precious metal.

- “In situ” extraction: involves pumping chemicals underground to dissolve the mineral containing the resource and then pumping the solution to the surface from which to extract the mineral resource (eg uranium extraction).

Double diaphragm pumps, while being used in all the types of extraction described above, are used more frequently within underground extraction processes. Let’s now see in what modality

Use of AODD pumps in dewatering activities

Air-operating double diaphragm pumps are widely used for mine dewatering operations. These operations consist of pumping mine water from lower basins and transferring it away from the working areas, usually to a central pond. This process keeps the work area free of deep water, increasing the safety conditions of the miners and the surrounding production environment. However, it is necessary to consider three important aspects related to the use of the correct pump technology:

- Liquid characteristic: if the water to be pumped and transported is particularly acid, it will be necessary to use steel diaphragm pumps to promote resistance to abrasive effects.

- Weight of the pump: in many cases the pumps are moved from one place to another in the mine manually without the aid of conveyors. In this case it will therefore be necessary to pay attention to the weight characteristics of the pump. For this reason, AODD pumps can be considered a versatile and effective solution.

- Pump material: the use of some materials may not be allowed within some specific mining sector. In this case it will be necessary to consult the local reference regulations. Also, in this case the versatility in terms of design and choice of materials becomes a winning factor in the field of AODD pumps.

AODD pumps for leaching operations

AODD pumps are used in the type of “placer extraction” where the rock and minerals are crushed and sieved and then rinsed by a filtering chemical that captures and extracts the mineral from the piles of crushed materials. In this case the task of the AODD Pump is to dispense and transfer the leaching chemical. The aspects to be taken into consideration are the following:

- Temperatures and Pressure: Chemicals are often dispensed at very high pressure and dosed in high temperature environments. In this case, the AODD pumps have conformity characteristics suitable for use in high temperature environments.

- Chemical Resistance: the chemicals used can be particularly harmful to the materials and the surrounding environment. In this case, the diaphragm pumps have all the suitable conditions to be able to resist abrasion and to keep the environment and workers safe.

- Explosions: the pumps can be used in conditions where there is a risk of gas leakage or explosion. Diaphragm pumps conforming to ATEX directives can be used in explosive or potentially dangerous environments.

AODD pumps for sedimentation ponds

The AODD pumps are used as part of the water treatment operations removed from the underground mine or from the surface extraction area. Water, usually placed in a sedimentation pond, can contain contaminants and in many cases, especially in coal mining, can be very acidic. To protect the environment, water must be neutralized and treated before being released into the environment. AODD pumps are used to dispense neutralizing chemicals, flocculants and other process chemicals. They are also used to transfer water to tankers if water removal and treatment involves moving to a different location. The factors to consider for the use of AODD pumps in this activity are as follows:

- Ability to treat viscous liquids often present in solid waste deposited inside the sedimentation ponds. In this case the diaphragm pumps can move liquids with high concentrations.

- Chemical Compatibility: the presence of corrosive elements requires a correct pumping technology in terms of materials and operating characteristics of the pump. In this case the choice of a diaphragm pump is a valid solution for the transfer of abrasive liquids or with solid elements in suspension.

Conclusions

DEBEM double diaphragm pumps can be used in a wide range of applications and extractions: from dewatering activities in aquifers to transferring drilling muds, washing and separating minerals to water and sludge treatment. For any type of information on AODD pump applications in the mining sector, do not hesitate to contact our sales team.