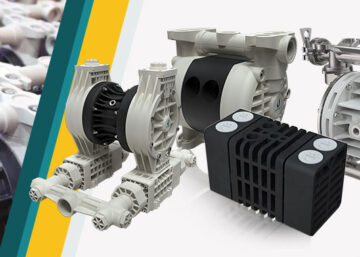

The pneumatic double diaphragm pumps (AODD), thanks to the excellent characteristics of versatility and reliability, have become a very widespread solution in various application sectors: from the petrochemical sector to the food sector, from the chemical sector to the mining sector. The design structure and the particular design configuration make them an ideal solution for the transfer of highly abrasive or viscous products. Within this article we briefly introduce the operation of this pneumatic pumps.

What are AODD pumps and how do they work?

Double diaphragm pumps belong to the positive displacement pump family and use compressed air as the main power source. In particular, the compressed air is transferred from one chamber to another through a shaft, positioned in the central section, which allows the chambers to move simultaneously. The front and rear movement allows the liquid to be moved from one chamber inside the drainpipe while at the same time the other chamber is filled with liquid. Depending on the type, composition and behavior of the solids in the pumped fluid, the AODD pump can be equipped with ball valves or “clapet valves”.

Application advantages of diaphragm pumps

Pneumatic double diaphragm pumps have many application advantages over other pumping technologies.

- Dry running: AODD pumps, if left running in the absence of liquid, ensure continuity of operation without causing damage to the pump components.

- Self-priming function: thanks to the ability to run dry, they can prime up to 6/7 meters without particular problems.

- Safe Design: Because the pumps are air driven, they are inherently safe within ATEX environments. Debem also presents models with carbon impregnation which makes the pumps conductive and suitable for the most volatile atmospheres.

- Versatile: Due to its simple design, these pumps are available in a wide variety of plastics and metals ensuring suitability for a wide range of fluids from water, oil, waste oil, diesel, acids, food and slurry.

- Easy installation: the pumps, thanks to the design configuration, can be easily disassembled, transferred and reassembled in any position within the system line.

The main differences in use between a diaphragm pump and a gear pump

Within this section we present a comparative table between the different potential uses of a double diaphragm pump and a pumping technology based on a type of gear pump.

| Features | AODD Pump | Gear Pump |

| Versatility in handling liquids | Guaranteed for a high variety of fluids with different viscosity characteristics. | Limited ability to handle liquids with variable viscosity or non-Newtonian fluids. |

| Dry running | Guaranteed without causing damage to pump components | Not allowed. |

| Management of abrasive liquids | Guaranteed by the configuration characteristics of the materials. | Not allowed. |

| Liquid contact with components | Not present | Present |

| Possibility of wear | Limited | Likely |

| Maintenance Needed | Low | Medium / High |

Conclusions

AODD pumps offer simple technology and reliable pumping for many fluids in many industries. A Debem technician is at your complete disposal to identify the most suitable type of pump for your application.