As already discussed in many previous articles, pneumatic double diaphragm pumps represent a safe and effective solution for the transfer of fluids and substances used within chemical production processes. The high versatility that characterizes this type of pneumatic pumps makes them a suitable solution for managing both basic chemicals and more complex and dangerous substances.

Elements of pneumatic double diaphragm pumps

The industrial plants operating within the chemical production processes are characterized by high technology and the efficiency conditions. Both features are necessary to guarantee a completely safe operation. Specifically, the components of chemical plants, in addition to having characteristics of resistance to aggressive and dangerous substances, must comply with particular functional requirements that make them suitable and reliable for use within the sector. Many of these requirements coincide with some of the main functional characteristics of pneumatic double diaphragm pumps.

- Double diaphragm pumps allow dry running without causing damage to components and without generating overheats that could cause unsafe operating conditions.

- AODD pumps are built with a wide range of chemically resistant materials, so they can handle virtually any type of substance.

- The operation of AODD pumps does not require electricity, which allows them to operate safely and reliably in explosive environments or when pumping flammable liquids.

- The construction components of the pumps do not require special mechanical seals and this makes them a very simple product in terms of maintenance and assistance.

- Diaphragm pumps are also characterized by favourable portability conditions that allow for high application mobility and consequent versatility of use within complex environments.

How does a double diaphragm pneumatic pump work?

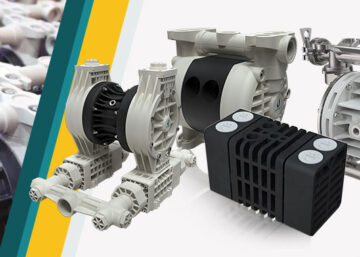

The solution offered by Debem for the chemical sector is the Midgetbox product: a pump that is characterized by extremely compact dimensions that can easily adapt to any context of use. The pump, entirely designed and built in Italy, has a patented anti-stall pneumatic circuit that allows it to operate in an extremely safe manner without the use of lubricated air.

Midgetbox is also capable of operating in self-priming mode and supports dry running without causing damage to pump components. The pump also allows accurate adjustment of the operating speed without causing pressure losses. Midgetbox is ATEX certified for Zone 1 and Zone 2 which allows it to be used in potentially explosive environments.

The Midgetbox pump has inside ball check valves equipped with springs, this allows the pump to be installed, not only in a horizontal position, like almost all pneumatic pumps on the market, but in any position you want, without compromising. correct operation.

All these characteristics have given the Midgetbox pump a truly high versatility of use, which combined with the wide choice of composition materials, allows to determine the best chemical compatibility with the fluid and with the environment without neglecting the variables of temperature and environmental risk.

Conclusions

Debem double diaphragm pumps intended for the chemical sector are designed in full compliance with the most important functional and safety requirements required by the sector. Contact our sales team immediately to understand the pumping technology most in line with the needs of use within the chemical sector.