The pneumatic double diaphragm pump (AODD) has earned a deserved reputation as the ideal technology for handling and transferring liquids in environments characterized by even high critical conditions.

AODD pumps excel in these types of applications because they have design features that allow them to offer simple and immediate operating conditions. The additional strengths are represented by the ability to self-prime, therefore the possibility of dry running in the initial phase of pumping and the ability to move fluids with solid elements inside.

It didn’t take long for companies to understand that, with these operational characteristics, double diaphragm pumps could become an ideal solution that can operate efficiently and safely in many fluid handling process applications. Many chemical processors have optimized their pumping and fluid transfer operations with four benefits that AODD pumps can provide in this area. Let’s take a closer look at all four strengths.

Low operating costs of AODD pumps for maintenance

Diaphragm pumps are not equipped internally with mechanical seals, as is the case in many types of centrifugal pumps. The elimination of expensive seals reduces maintenance costs and allows for “plug and play” operating conditions avoiding long periods of machine downtime.

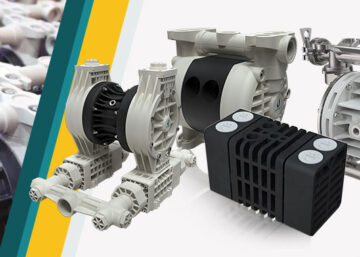

The various models of Debem pumps for the chemical industry offer many operational advantages, including high ease of maintenance and rapid assembly and disassembly. Debem pumps can be integrated with a complete series of accessories according to the specific needs of use. A wide range of Debem original spare parts can support any maintenance or component replacement needs.

The construction materials of double diaphragm pumps

The construction of a quality pump is essential when there is the need to transport and handle dangerous chemical fluids. In this case, the use of an AODD pump designed with suitable materials is important for the safety of the entire system. In order to meet these needs, DEBEM’s AODD pumps are available in a wide range of construction materials to meet different handling and pumping needs. Common materials for Debem chemical pumps include Glass filled polypropylene, Carbon filled polypropylene, PVDF, ECTFE, PTFE, AISI316, AISI316 L and Aluminum.

The versatility of diaphragm pumps

Chemical transformation processes involve the completion of very complex industrial operations along the entire production chain. Plant operators must therefore identify a pumping technology that can operate reliably and efficiently at any point in the production hierarchy. The design and operation of Debem’s AODD pumps allows them to transfer a wide range of liquids with different handling characteristics. One of the most important is the viscosity, or the thickness of the liquid being transferred. Operation of AODD pumps virtually eliminates product slip regardless of fluid viscosity.

Conclusions

Debem’s AODD pumps, thanks to their simple but innovative design, have proven to be able to constantly meet the demands of chemical processing companies, building an excellent reputation as an ideal pumping technology for aggressive liquids or particularly critical application environments. Contact our sales team for more information on selecting AODD pumps for the chemical industry.