What centrifugal pumps are and how they work

Centrifugal pumps are part of the family of fluid-dynamic pumps where the pumping of the fluid takes place by means of a dynamic action generated by the movement of the fluid itself. Centrifugal pumps use a centrifugal force field to impart energy and speed to the liquids to be transported. Through this mechanism, centrifugal pumps are able to transform speed into an energetic flow of pressure. The forces that come into play within the mechanism are the following:

- speed as a form of energy imparted to the liquid

- the pressure converted by the action of kinetic energy.

The main elements of a centrifugal pump

The main elements of a centrifugal pump are as follows:

- Impeller: main element of a centrifugal pump has the purpose of pumping the liquid inside the pump by means of the centrifugal force generated by the special fins that compose it. By rotating the impeller, centrifugal force is generated which moves the liquid from the center to the outside of the pump. The impellers differ in shape and materials according to the required performance and the type of liquids to be transported.

- Suction port: central element of the pump has the function of channeling the pumped fluid through the impeller which radiates it towards the pump body.

- Shaft: part on which the impeller is fixed and usually connected to the electric or combustion engine.

Classification of centrifugal pumps

Centrifugal pumps can be classified according to the position of the transmission shaft that moves the impeller. This classification also indicates a particular operation determined by the reference application context. In particular:

- horizontal centrifugal pumps are mainly used outside the tank;

- vertical centrifugal pumps can be partially immersed inside the liquid or tank.

Centrifugal pumps can also be divided according to the power supply of the engine which can be electric (electric pumps), combustion (motor pumps).

A further differentiation can be made for magnetic drive centrifugal pumps where the impeller is not directly connected to the motor through the shaft, but is set in motion by a magnetic force generated by the interaction of two magnets.

Advantages of Centrifugal Pumps

Thanks to their versatility, centrifugal pumps are suitable for use in various industrial and civil application sectors. The main advantages that this type of pump guarantees are the following:

- they are resistant to wear thanks to the construction configuration and the use of materials that make them particularly suitable for handling acid solutions and corrosive liquids;

- they guarantee a constant capacity and the possibility of working at high rotation speed, thus reducing the structural dimensions for a given capacity;

- they are able to transport a wide variety of liquids even with particular characteristics or with suspended solid elements.

Application sectors of centrifugal pumps

Thanks to the advantages listed above, centrifugal pumps can be used in various application contexts:

- Agricultural sector: centrifugal pumps can be used for all water handling needs.

- Marine sector: to support the needs of ballast water handling to give safety and efficiency to navigation maneuvers.

- Water Treatment Sector: crucial use in all phases of wastewater treatment and in water purification processes in civil and industrial plants.

- Electronics and automotive industry: the pumps can be used in complex industrial processes: ie in the production of printed circuits, in surface treatment and in galvanic baths.

- Petrochemical sector: the wide availability of materials makes centrifugal pumps suitable for pumping liquids characterized by very high temperatures.

- Chemical sector: centrifugal pumps are used in the case of pumping highly corrosive fluids.

DEBEM centrifugal pumps

Debem presents a wide range of centrifugal pumps that differ essentially in the construction configuration, construction materials and scope of use.

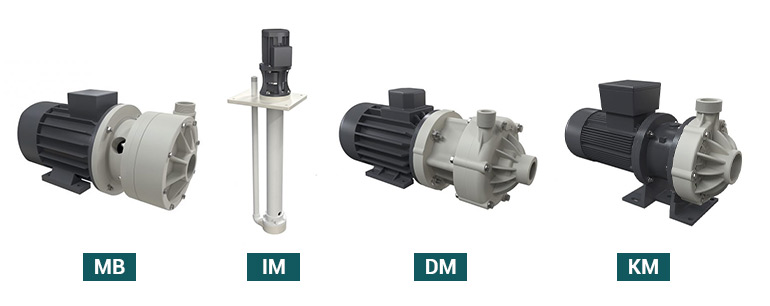

- The Horizontal Centrifugal Pumps of the MB series built in Polypropylene or PVDF and equipped with an electric motor are able to handle minimally viscous fluids and / or with small solid parts in suspension. They are suitable for use in the automotive sector, in water and sludge purification operations, in the chemical and galvanic industry.

- IM Vertical Centrifugal Pumps can be made of Polypropylene or PVDF and are suitable for immersion installation. The sectors of application are the chemical sector, the metallurgical and galvanic industry, the goldsmith sector and the treatment of water and sludge.

- The magnetic drive pumps of the DM series represent a valid solution for the handling of acidic and corrosive substances thanks above all to the particular design configuration that makes them free of metal parts in contact with the transported fluids. The fields of application include the automotive sector, the chemical and galvanic industry and purification and sludge operations.

- The KM series magnetic drive pumps represent a further technological evolution of the DEBEM DM range capable of ensuring greater flow rate and energy efficiency for more important pumping needs.

Conclusions

Debem, thanks to the wide range of solutions and in-depth experience in the sector, is able to satisfy any type of request in the field of centrifugal pumps, both for civil and industrial uses. Contact the sales team to better define the needs and choose together the best solution in terms of performance and results.