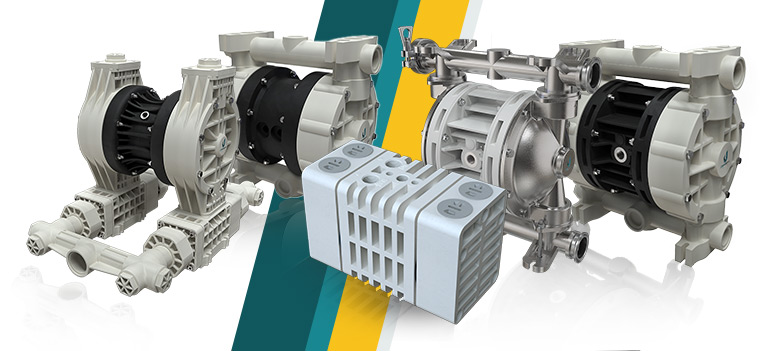

Double diaphragm pneumatic pumps

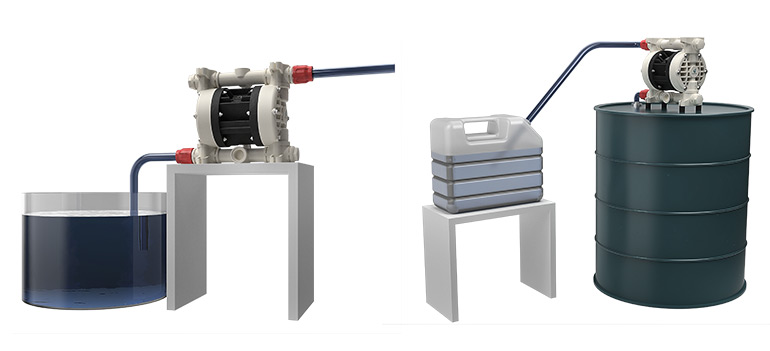

We have repeatedly defined a pneumatic double diaphragm pump (AODD) as a type of positive displacement pump consisting of two pumping chambers which are filled and discharged alternately by the movement of flexible membranes. The pneumatic distributor alternately feeds the air chambers, positioned behind the diaphragms, favoring the pumping action. AODD pumps are typically used for a variety of transfer applications and can handle a wide variety of fluids, including viscous, abrasive and shear sensitive fluids. Double diaphragm pumps are characterized by sturdiness, reliability and ease of maintenance. Thanks to the use of specific materials, they can be the ideal solution for operation in hazardous or potentially explosive environments.

What are lobe pumps?

Lobe pumps consist of a shaped chamber containing two lobe rotors that rotate synchronously on parallel axes. The rotation of the lobes favors the thrust of the liquid from the suction mouth to the delivery one, creating a continuous flow. Lobe pumps are used in a wide variety of sectors, including the packaging and paper industry, the chemical sector, the food and beverage industry and the pharmaceutical sector.

How lobe pumps work

Lobe pumps are similar to external gear pumps in that the fluid flows around the inside of the casing. Unlike external gear pumps, however, the lobes do not come into contact with each other due to the presence of external timing gears. As the lobes exit the mesh, they create expanding volume on the inlet side of the pump and favor the flow of liquid which becomes trapped by the lobes as they rotate. The liquid travels inside the pockets between the lobes and the casing. The movement of the lobe gears eventually pushes the liquid through the outlet port.

Advantages of using AODD pumps over gear pumps

Below we have drawn up a list of advantages related to the use of AODD technology compared to the use of gear pumps.

- Self-priming capacity: double diaphragm pumps are able to operate in self-priming mode while the suction capacity of lobe pumps is rather limited.

- Energy optimization and shutdown during zero flow: double diaphragm pumps optimize energy consumption during zero flow and then restart autonomously once the valve opens. Lobe pumps require the presence of a relief valve during “deadheaded” operations with a limited time for the use of the bypass.

- Reduced component wear: AODD pump components are subject to limited wear as the design features mean that only some parts are in contact with the fluid. The situation is different for lobe pumps where many rotating parts are wetted by the fluid with an increase in the possibility of damage and wear.

- Ability to manage solids: AODD pumps ensure excellent management of solid elements that can have a size equal to that of the pump inlet. This possibility is more limited in the case of lobe pumps that can handle solid elements of medium size.

- Ability to handle abrasive fluids: AODD pumps, thanks to the use of specific materials and the design configuration, are able to handle aggressive and abrasive substances. However, this possibility is not guaranteed by lobe pumps.

Choose the most suitable diaphragm pump for your system

The choice of the most suitable pumping technology is a decisive and fundamental factor to guarantee the good operation of any application system. For this reason, DEBEM is able to support the most complex design and application needs. Contact our team now in order to identify the pumping technology that best suits your needs.