A drum transfer pump is a portable pump specifically designed to transfer fluids from storage tanks or drums safely and efficiently. The drum pumps are available according to different feeding models (with electric or pneumatic motor) and dimensional configuration. The variables that affect the choice of the model clearly refer to the type of fluid to be pumped and the characteristics of the application environment.

Element of the drum transfer pumps

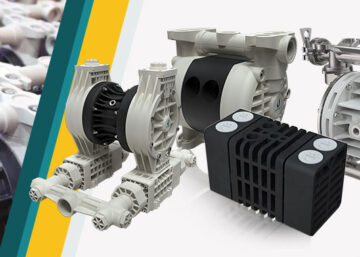

Debem drum transfer pumps represent a valid solution for the management and transfer of fluids from very large tanks. This type of pump usually consists of three elements:

- a motor unit located on the top of the immersion tube and which will be positioned outside the container.

- an immersion tube of variable length depending on the height of the tank. Inside the tube there is a coated vertical metal shaft, connected to an impeller that moves the fluid to be transferred.

- A pump section located at the lower end of the immersion tube which has the task of extracting the liquid and pumping it through the tube.

The power supply of the motor can be electric or pneumatic while the pumps can be supplied in different materials such as Polypropylene, PVDF or AISI 316.

How does a drum transfer pump work?

A drum transfer pump is driven by the motor placed on the end of the immersion tube. The latter is protected by a sealed column inside which the fluid is pumped to the discharge port positioned at the end of the immersion tube.

The materials of the drum transfer pumps

In this type of pump there are many pump components that come into contact with the fluid to be transferred. It is therefore important that the parts in contact with the fluid:

- are resistant to corrosion which could cause component wear or pump malfunctions.

- They are safe to use at different temperatures in the operating environment.

For this reason, drum transfer pumps can be built with the use of the following materials:

- PP (polypropylene): suitable for transporting acidic, alkaline or detergent substances.

- PVDF: suitable for carrying bleach, chromic acid, citric acid or sulfuric acid.

- Stainless Steel: useful for the transfer of aggressive or flammable substances.

Advantages of Drum Transfer Pumps

The main advantages related to the use of drum transfer pumps mainly refer to the reduction of risks deriving from the manual handling of large capacity containers containing dangerous or toxic substances. The additional benefits of use are as follows:

- versatility in terms of design and materials that make them suitable for efficiently transporting aggressive fluids.

- Interchangeability of the elements that allow the pump to adapt to the dimensional characteristics of the tank to be emptied or to the characteristics of the fluid to be pumped.

- Operational flexibility thanks to the portability features that make them a suitable tool for environments with little space or to be moved from one place to another in the system.

Application sectors of drum transfer pumps

The application sectors of the drum transfer pumps are the following:

- Paint industry: for the transfer of inks, paints, solvents.

- Chemical industry: for the transfer of substances, resins, solvents and acids.

- Oil industry: for the transfer of fuels, motor oils, fuel oils.

Conclusions

In order to maximize the high configuration potential of this type of pump, it is important to evaluate a series of very important variables: operating environment, fluid to be transported, size of the tanks to be emptied. The Debem team is at your disposal to provide you with the best configuration advice. Contact him now for information.