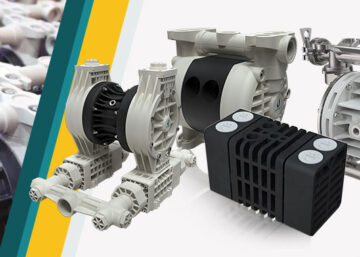

In our previous posts we have explored in detail the numerous benefits that diaphragm pumps ensure to the various sectors of use in terms of efficiency, performance and safety. AODD pumps have unique characteristics of versatility that make them suitable for use in various application sectors. However, there are some industrial operations that can benefit very efficiently from this type of pump. Let’s find out together in this article.

Advantages of diaphragm pumps

Before listing the high potential use factors, we summarize together the main advantages of double diaphragm pumps:

- The AODD pumps have no mechanical elements inside them so they are less subject to the problems caused by abrasion.

- The pumps are self-priming and can run dry without any problems. The wide choice of materials for membranes, spheres and gaskets makes them suitable for handling abrasive, corrosive or fluids that are very sensitive to cutting.

- The AODD pumps work only with compressed air, they have no electrical parts inside, which makes them ideal for use in hazardous environments.

- The design configuration and design features make them very easy to maintain and possibly repair in case of internal parts failures.

- This type of pump is very easy to transport and can be easily moved to different parts of the system.

- AODD pumps are equipped with numerous certifications that make them suitable for use in environments with explosive potential (ATEX – IECEx certification) or in the food sector (FDA certification).

Applications where maximum efficiency can be obtained from AODD Pumps

DEBEM double diaphragm pumps, which naturally have all these application advantages, find use with a high efficiency potential in the following applications.

1. Transfer of chemical or hazardous fluids

AODD pumps are commonly used for transfer as they are able to safely handle a high variability of fluids without damaging them or changing their chemical-physical characteristics. The types of fluids that can be handled with diaphragm pumps include:

- solvents and detergents;

- paints, inks or pigments;

- aggressive or dangerous chemicals;

- viscous fluids.

2. Water Removal and Dehydration

Removal of water or drainage activities are very common operations for AODD pumps. In any episode of water accumulation within an area, the AODD pump becomes a key tool for managing dehydration operations. The main application contexts concern:

- building or industrial sites;

- industrial wells;

- drainage tanks near industrial plants;

- mining or quarrying sites.

3. Spraying and Cleaning

AODD pumps guarantee efficiency and durability and can be an ideal tool for cleaning surfaces or spraying various types of products. The particular design configuration and the use of appropriate materials make the AODD pump capable of delivering cleaning chemicals, paints and other fluids at a constant speed while still ensuring suitable conditions of resistance to corrosion. The main applications are the following:

- surface cleaning;

- spraying of detergents;

- spraying of protective fluids;

- paint spraying;

4. Dosage

The technical characteristics of diaphragm pumps make them ideal for the management of dosing operations of particular types of fluids in recipients with high dimensional variability. The main manageable operations are:

- Dosing of chemical products;

- Dosing systems for paints and solvents;

- Dosage of glues and solvents;

- Dosage of food substances;

- Dosing of chemicals for water purification.

Conclusion

Contact our sales team to find out the chemical compatibility, the suitable material and the type of AODD pump best suited to your application. Our experts are at your disposal to help you select the product that best suits your needs.