Within the vast industrial landscape, diesel fuel transfer represents one of the most delicate and crucial operations. Maintaining proper safety conditions and efficiency becomes an essential goal to ensure the safety of industrial processes, operators and the surrounding environment. Within this context, Debem comes into play with reliable and innovative solutions.

The risks associated with the use of diesel transfer pumps

The safe transfer of diesel fuel between tanks is a challenge that many industries face on a daily basis. Here are some of the main risks associated with it:

- Static electricity: The presence of static electricity can cause diesel fuel vapors to ignite, making the transfer process potentially dangerous. This phenomenon can occur when diesel fuel is transferred rapidly, generating an electrical charge that, if not dissipated, can ignite the flammable vapors.

- Electrical connections: The use of pumps with electrical connections increases the risk of sparks from malfunctions or short circuits exposing the surrounding area to serious burst or fire hazards.

- Diesel fuel leaks: Poor management or a faulty pump can lead to diesel fuel leaks that not only waste valuable resources, but also create environmental and safety hazards. A puddle of diesel fuel can become a slippery area or, in the worst case, a source of fire if exposed to a heat source or sparks.

Diesel fuel transfer operations, if not handled carefully and with the proper equipment, can cause potentially dangerous situations. It is essential for companies to take preventive measures and have the proper equipment to ensure safe operations and protect the surrounding environment.

Double diaphragm pumps: a safe and efficient solution

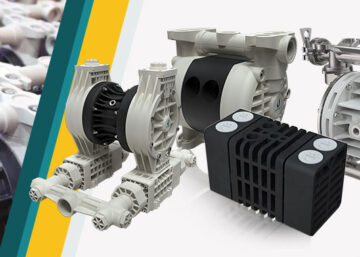

Double diaphragm pumps are an effective response to the expressed needs of operators engaged in the transfer processes of combustible liquids or fuels such as diesel fuel. AODD pumps, thanks to their unique construction configuration, can efficiently and safely address the challenges associated with diesel fuel transfer. Here are some of their advantages:

- Mechanism safety: Due to the special design configuration and compressed air operating mechanism, these pumps significantly reduce the risk of sparks and ignition. The absence of electrical components eliminates the danger of short circuits or electrical malfunctions.

- Operational safety: The absence of electrical power allows double-diaphragm pumps to operate safely even in the vicinity of potential static electricity accumulating vehicles. Their ability to operate remotely, thanks to the air supply line, increases the safety conditions of the system.

- Efficiency: The advanced design configuration combined with the innovative membrane technology ensure safe, precise and consistent transfer of diesel fuel, minimizing the risk of leakage and optimizing flow throughout the transfer process.

- Ease of control: When transferring large quantities of diesel fuel, it is essential to monitor the tank level. These pumps can be integrated with liquid level monitors, which stop the transfer operation when the tank reaches a predefined level.

- Portability: These pumps can be vehicle-mounted or even hand-carried in the field, making them extremely versatile and suitable for a variety of applications.

- Ease of maintenance: One of the main features of AODD pumps is ease of maintenance. The air valves are easily accessible from the outside, allowing quick interventions and reducing downtime.

Because of these advantages, double diaphragm pumps stand out not only as a viable alternative, but as a solution of excellence for diesel transfer operations. Their combination of safety, efficiency and durability makes them ideal for combustible liquid transfer operations, ensuring optimal safety conditions and excellent performance at the return-on-investment level.

Why choose Debem AODD pumps for diesel fuel transfer operations?

Debem double diaphragm pumps offer several advantages that make them the ideal choice for diesel fuel transferring.

Technology of Debem diesel fuel pumps

Special construction technology allows Debem AODD pumps to be a practical and versatile solution for handling all transfer operations in different industrial applications. Their ease of maintenance allows for quick intervention in the field by reducing downtime while the high operational safety conditions minimize the risks associated with transfer operations, such as fire or explosion.

Materials of Debem diesel pumps

Debem pumps are made of high-quality materials such as aluminum and stainless steel. These materials ensure strength and durability, making the pumps ideal for heavy-duty industrial applications. In addition, the use of conductive plastic materials with carbon fiber increases the safety rating of the Debem pump and makes it particularly suitable for use in potentially explosive environments.

Debem diesel transfer pump certifications

ATEX certification attests to the safety of Debem pumps in potentially explosive environments. An ATEX-compliant double-diaphragm pump is an essential choice if you want to operate safely within processes involving the transfer of combustible liquids such as diesel fuel.

The reliable choice: Debem double diaphragm pumps

Debem’s double diaphragm pumps are the ideal solution for diesel fuel transfer needs within various industries. Thanks to their innovative design configuration, they can deliver excellent results in terms of safety, efficiency and operational performance. In case of specific needs or configuration requests, please do not hesitate to contact our Debem sales team. We are fully available to provide information, quotations and advice on the most suitable configuration for your specific transfer needs.