Debem Test-Lab

Debem presents an internal laboratory dedicated to the analysis and improvement of products: the DEBEM TEST-LAB. The first IECEx certified laboratory for pneumatic pumps in Italy, the Test-Lab is open to the public for technical courses and allows for certified tests to be commissioned by customers.

The analysis and improvement laboratory consists of two air lines for supplying pumps up to 6000 NL / min and three fluid lines for flow rates up to 3000 LT / min and has a compartmentalized anti-cavitation polypropylene tank with a capacity of 4000 liters.

The Test-Lab is equipped with certified technologies and technical equipment to guarantee the best performance. Within the laboratory it is possible to:

- carry out the analysis of air consumption, flow rates and head, thanks to certified digital instrumentation.

- collect data and graphs centrally.

- issue test certificates.

Within the Test-Lab 3 different types of tests are mainly carried out. We will now go into them individually below.

Performance test

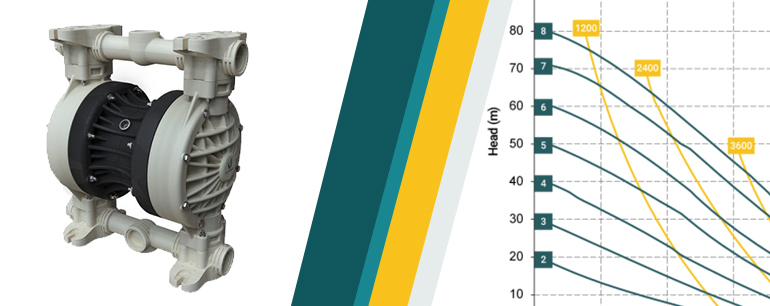

A first type of test carried out within the Debem laboratory is the Performance Test, aimed at measuring the performance of a pneumatic pump under certain operating conditions. In turn, a performance test can be of three types:

- Duty Point

The duty point is the intersection between the pneumatic pump performance curve and the characteristics of the pumping system. Through the Duty Point test, the Customer specifies certain operating conditions (such as head and flow rate) with the aim of obtaining some missing data (such as the necessary supply pressure and the relative air consumption). - Single curve

The single curve test aims to profile the complete performance trend of the pump, based on a precise supply pressure. In this case, the Customer indicates a specific pressure of interest and the configuration of the zero head pump is carried out. It then continues by carrying out successive measurements of flow rate and consumption by increasing the head in steps of 10 meters, until the delivery is completely closed. - All curves

In this test we do not start from an exact pressure specified by the Customer, but the set of “Single curve” measures is repeated for the supply pressures 2, 3, 4, 5, 6, 7, 8 bar (except if the pump has a different permissible operating range).

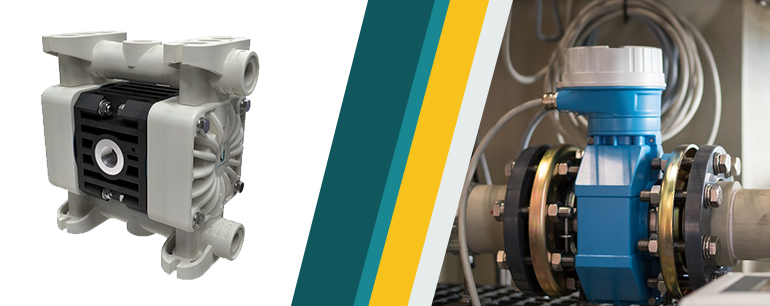

Hydrostatic Test – Hydraulic / Hydrostatic Test

The Hydrostatic Test or Hydraulic Test is a diagnostic technique to perform high pressure hydraulic tests to identify any leaks or defects.

The pump, when not powered, is loaded with water under pressure (typically 1.5 times its design pressure).

After 30 or 60 minutes in these conditions, depending on the customer’s request, it is verified that the pressure has not dropped and therefore there are no detectable leaks.

Function Test – Running Test

The Operation Test or Running Test is performed for 4 hours, with the aim of demonstrating that the pump works in stable conditions and all variables are within the acceptance range.

More specifically, the pneumatic pump is operated for four hours, at the work point indicated by the customer. After successfully completing the function test, the pump is disassembled to be subjected to a visual inspection and verify the absence of anomalies (such as losses or changes in performance, wear, etc.).

Conclusions

Debem, thanks to the collaboration in close contact with external laboratories, is able to satisfy any type of request in the field of testing, also providing specific types of tests such as penetrating liquids, radiographs, chemical analyzes (P.M.I.).

Contact our team to get more information and request the service that meets your needs.