The use of double diaphragm pumps in the automotive sector guarantees safety and reliability within an extremely rigid environment in terms of quality and safety. Let’s discover the advantages offered by this type of pump.

The requirements of the automotive sector

The automotive sector, like the chemical, pharmaceutical and food sectors, has high compliance requirements in terms of quality and safety. Fully adhering to the rigorous standards required by the automotive industry means configuring an efficient and at the same time safe and reliable production system using the best production factors available on the market.

The use of double diaphragm pumps in the automotive sector is part of a context where high levels of productivity, reliability and safety become essential elements within the production process.

In this post we want to learn more about how AODD pumps represent a solution able to safely face the rigid operating conditions required by the production of automotive components.

Advantages of AODD pumps in the automotive sector

The pneumatic double diaphragm pumps (AODD) are designed considering the highest quality and compliance with the rigorous environmental standards found in the automotive industry.

In fact, AODD pumps offer:

- Reliability and Durability: The unique design configuration of diaphragm pumps allows a pump to tackle a variety of applications without costly motor drives or sizing calculations.

- Size and versatility: the small size of the AODD pumps ensure high versatility thanks to the ease of movement within the production line.

- Ease of installation: this strength together with the low maintenance requirement minimizes downtime and production interruptions.

- Resistance: the diaphragm pumps, thanks to the design configuration and the materials used, guarantee high resistance to various types of fluids.

- Certifications: diaphragm pumps can be equipped with ATEX and IECEx certifications to be used safely in environments characterized by explosive risk.

The areas of use of diaphragm pumps within the automotive sector

The common areas of application of diaphragm pumps within the automotive sector can be summarized in the following points:

- Painting systems: surface cleaning systems and spray painting and solvent distribution systems.

- Metal finishing plants that use immersion systems or systems for galvanizing metals.

- Lubrication systems: systems for the transfer of lubricants and for the pumping of molding fluids.

- Mixing of the rubber compound to produce wheels and tires.

- Management of wastewater from the production plant: Filtration of wells, removal of waste and waste from the production process (metal shavings, particulates).

- Loading and unloading systems for the transfer of oil, fuel, engine coolants, diesel, and various types of petrol.

- Industrial and commercial car wash systems for vehicle cleaning.

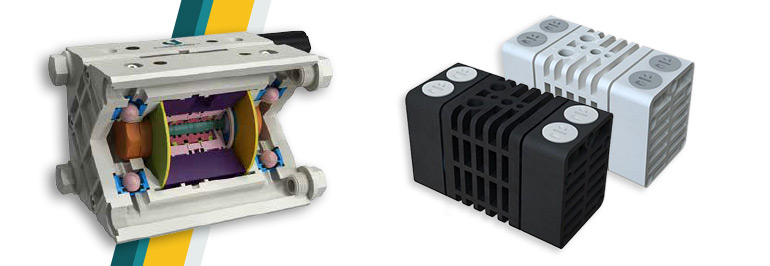

Debem’s AODD pumps for the automotive sector

DEBEM AODD pumps represent a valid solution for use within the automotive sector. Debem diaphragm pumps are frequently used within systems for spraying release agents and for the distribution of paints and solvents on centralized systems. Debem automotive pumps are also used in tropicalizing liquid transfer systems for radiators, fuel pumping and fuel additives.

Thanks to the design configuration and reduced dimensional characteristics, the AODD pumps of the CUBIC line can be directly installed on car wash systems. Debem AODD pumps are equipped with ATEX and IECEx certification and can therefore be used to transfer flammable or explosive liquids such as diesel, biodiesel, and various types of petrol.

The AODD pumps offered by Debem can be configured by selecting a wide choice of materials available which makes them extremely versatile for countless application uses. Our team of experts will be able to identify the perfect pump to meet any application need.