Debem is a company that specializes in the design and manufacture of ATEX certified diaphragm pumps, meaning they adhere to the ATEX 2014/34/EU directive for the handling of equipment suitable for use in environments with explosive hazards. Within this article, in addition to providing an overview of ATEX certification, we will delve into the main reasons why many companies use ATEX diaphragm pumps.

The explosive risk within industrial sectors.

Many industrial sectors are characterized by high risks that can harm the surrounding environment or the health of workers. One of the main hazards is the explosive hazard that characterizes many production processes: from the chemical and pharmaceutical industries to the mining sector, from the hydrocarbon sector to the paint industry. Within these sectors it becomes essential to prevent explosion hazards caused by even unintentional phenomena such as: electrical sparks, electrostatic charges, flames or hot gases, electromagnetic waves, overheated surfaces or chemical triggers. If production processes are subject to these types of hazards, it is imperative that companies adopt procedures and employ equipment that can minimize each hazard case.

The ATEX directives for regulating explosive hazards.

The European Union has adopted two directives to regulate all measures aimed at supporting health and safety in potentially explosive atmospheres.

- ATEX Directive 99/92/EC: classifies zones according to the existence of “explosive atmospheres” and specifies the criteria under which industrial products can be used within these zones. The directive also sets minimum requirements for health and safety in workplaces with potentially explosive atmospheres.

- Directive 2014/34/EU: requires manufacturers of equipment used in potentially explosive atmospheres to adopt certification for the products and equipment used.

The ATEX regulations strictly classify products, zones, sectors and areas according to a variable hazard scale, establishing precise design and construction rules for electrical or mechanical equipment used in hazardous areas. The goal of the Directive is to eliminate or prevent the creation of hazardous triggers capable of causing explosions.

Why are ATEX certified pumps important for corporate safety?

As we have seen within many industries, instances can occur, even unintentionally, where certain portions of flammable or oxidizing substances come into contact and, in the presence of a trigger, generate a combustion or explosion. All equipment (including diaphragm pumps) that is used in these types of atmospheres must be ATEX certified according to the degree of protection offered. ATEX Certification distinguishes risk according to the nature of the explosive product (Gas Group or Dust Group) and its ignition temperature (Class).

Take all safety measures with DEBEM’s ATEX pumps.

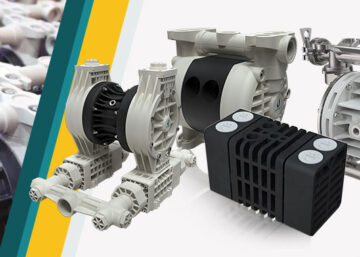

An ATEX-compliant double diaphragm pump is an essential choice if you want to operate safely within areas where there is a risk of explosion. The pneumatic pumps of the CUBIC, BOXER, RC, FULLFLOW line and the pneumatic pulsation dampeners of the EQUAFLUX line are ATEX-certified products and are manufactured in explosion-proof execution at the standard level for use in ZONE 2 and ZONE 22 (presence of flammable gas and dust) and upon request for use in ZONE 1 and ZONE 21.