Company profile

To enhance both efficiency and safety in the handling of concentrated acid solutions, a company specialising in chemical logistics chose to implement the Boxer 251 pneumatic double diaphragm pump for fluid transfer. The system is used to handle acids such as phosphoric, hydrochloric, and sulphuric acid, transferring them from mobile tanks to storage or treatment facilities. The operation takes place in demanding environments where chemical resistance, ease of transport, and fast emptying are critical.

- CUSTOMERCompany specialising in chemical logistics

- INDUSTRYChemical

- SOLUTIONBoxer 251 in PVDF, PTFE and Santoprene membranes, PTFE balls and seals

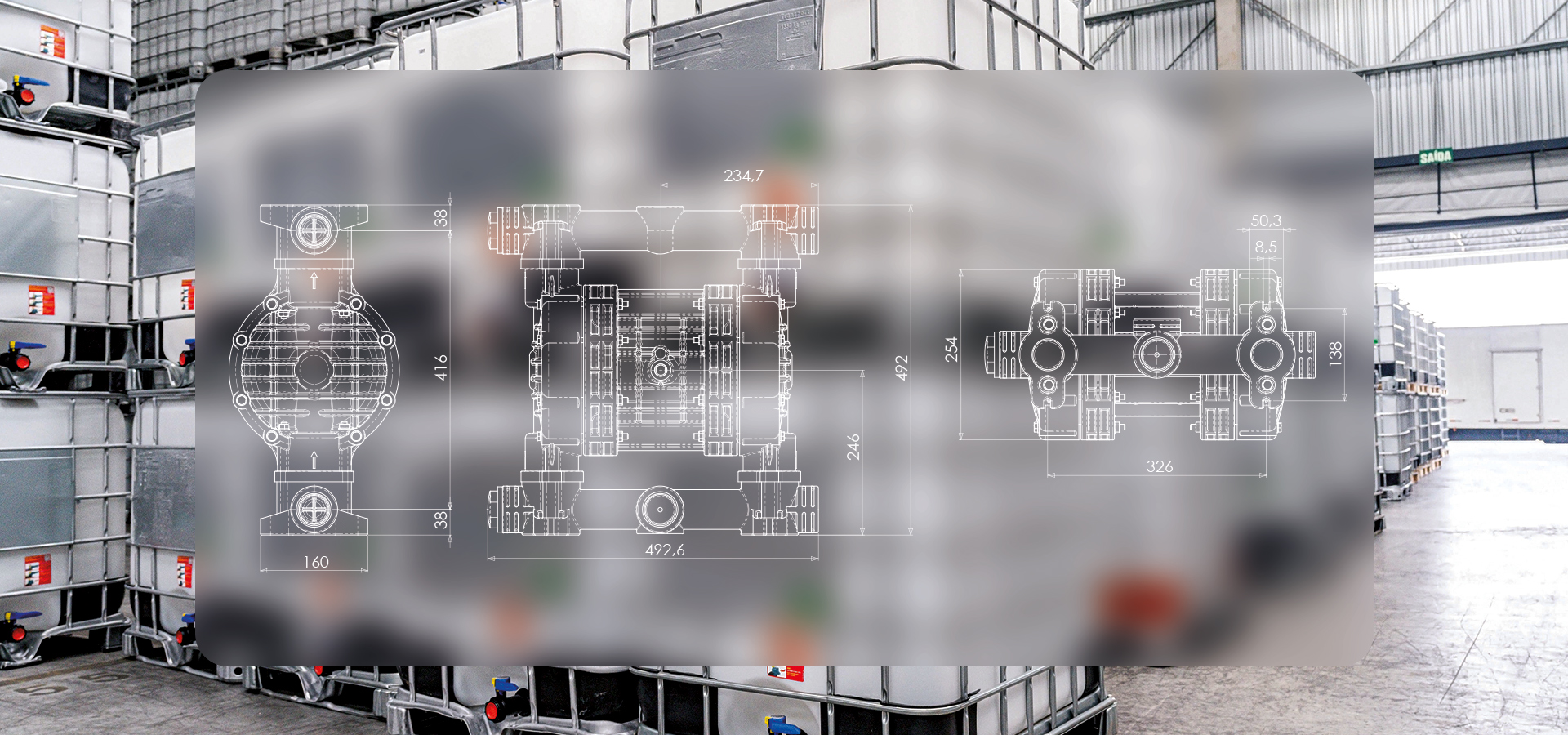

- MODELBOXER 251

Application of BOXER 251: the chemical pump for acid

The Boxer 251 double diaphragm pneumatic pump in PVDF has been installed on vehicles used for the delivery of acids. It is used for:

- Transferring acid solutions (e.g. hydrochloric, phosphoric or sulphuric acid)

- From tankers to IBCs or drums

- To fixed storage tanks or treatment lines

The system enables fast and safe operations, even in environments where electrical power is unavailable or unsuitable due to ATEX or safety constraints.

Application of BOXER 251: the chemical pump for acid

The Boxer 251 double diaphragm pneumatic pump in PVDF has been installed on vehicles used for the delivery of acids. It is used for:

- Transferring acid solutions (e.g. hydrochloric, phosphoric or sulphuric acid)

- From tankers to IBCs or drums

- To fixed storage tanks or treatment lines

The system enables fast and safe operations, even in environments where electrical power is unavailable or unsuitable due to ATEX or safety constraints.

Use of Boxer 251: pump for transferring acids

The company works continuous shifts to supply external plants and needs to transfer variable volumes from 100 to 500 litres of acid solution per operation, ensuring:

- Safety during transfer operations

- Compatibility with different acids

- Protection against leaks or vents

- Ease of installation and maintenance

The pump is powered by an onboard compressor, with pressure regulated between 4 and 6 bar, and is controlled via a manual valve.

Pump for transferring acid solutions: why BOXER 251?

The installation of the Boxer 251 has led to significant improvements in daily operations:

- Increased safety thanks to the absence of rotating seals and fully pneumatic operation

- 30% reduction in transfer times compared to the previous peristaltic pump system

- Easy to manage even in outdoor environments or with mobile operations

- Minimal maintenance: PTFE+Santoprene membranes have demonstrated high durability even with highly concentrated acids

- Universal compatibility with the main fluids handled without the need to change internal materials

Results obtained with the Boxer 251 acid pump

The Boxer 251 in PVDF has proven to be the ideal solution for the mobile transfer of acid solutions, combining chemical resistance, mechanical robustness and ease of use in a compact and reliable system.

Thanks to its modular design and wide range of compatible materials, the pump is ready to adapt to other aggressive fluids in the customer’s logistics environment, ensuring operational versatility and compliance with safety regulations for the handling of hazardous substances.