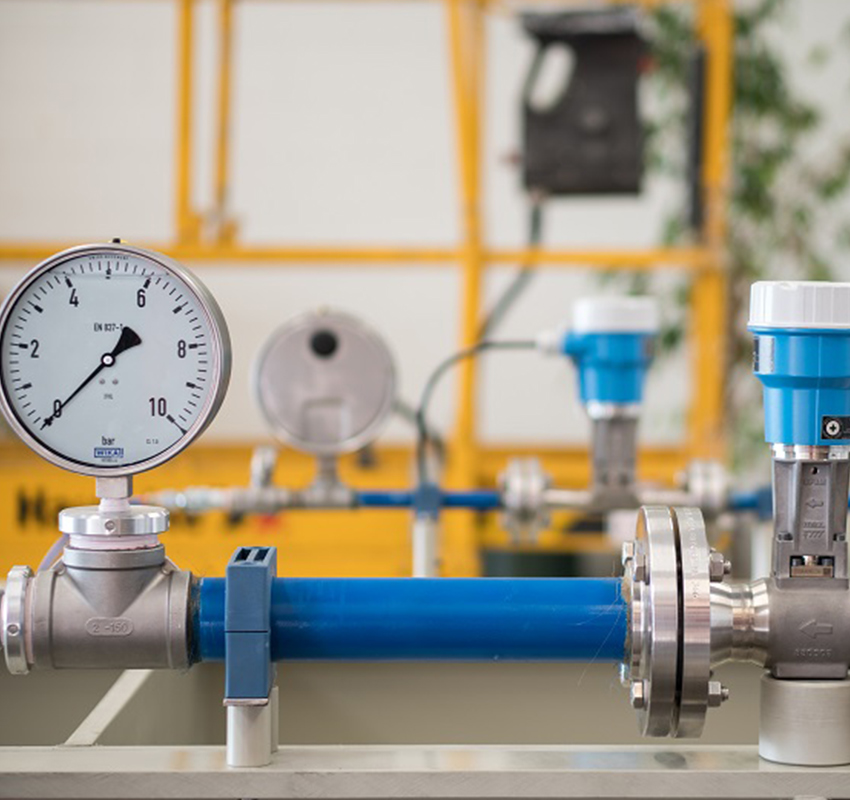

Analysis and improvement laboratory

We are very happy to present the new DEBEM TEST-LAB, an internal analysis and product refinement laboratory. Open to the public for technical courses and certified tests for customers, it is Italy’s first IECEx certified laboratory for air-operated pumps. Consisting of a 4000-litre polypropylene anti-cavitation tank with a compartmentalised structure, the TEST-LAB features two air lines to supply the pumps up to 6000 NL/min and three fluid lines to provide up to 3000 L/min. The technical equipment includes digital instruments certified to analyse air consumption, flow rate and hydraulic head, with a centralised data collection and graphics for issuing test certificates.

Performance test

A performance test measures the performance of a pump in specific operating conditions. There are three types of performance tests:

1. Duty Point

The customer specifies certain operating conditions and is interested in the missing data. For example they could set an hydraulic head and flow rate and need to know the supply pressure necessary and the relative air consumption.

2. Single curve

The customer specifies an exact pressure that they are interested in. The pump is configured with an open outlet, and consecutive measurements are made of the flow rate and consumption, increasing the hydraulic head in 10-metre steps, until the delivery is closed completely. This will provide the complete progress performance of the pump referred to that supply pressure.

3. All the curves

Instead of using a pressure requested by the customer, the set of “single curve” measurements is repeated for the supply pressures 2, 3, 4, 5, 6, 7, 8 bar (unless the pump has a different permitted operating range).

Hydraulic / Hydrostatic Test

The pump, not supplied, is loaded with pressurised water (usually equal to 1.5 times its design pressure). It is usually left in these conditions for 30 or 60 minutes, based on the customer’s requests. When the time expires we check that the pressure has not dropped and that therefore there are no leaks.

Running test

The pump is run for four hours, at the operating point indicated by the customer. At the end of the four hours we check that there are no faults (such as leaks or changes in performance, etc.). Moreover Debem, by collaborating in close contact with external laboratories, is able to provide other types of specific tests, such as penetrating liquids, X-ray photography and chemical analyses (P.M.I.).