Company profile

The customer is an established operator in industrial and civil liquid waste management, with over 25 years of experience in the collection, treatment and disposal of wastewater, chemical sludge and high-solids mixtures. It manages plants distributed throughout the country and serves sectors such as chemical, pharmaceutical, food and manufacturing. Operational safety and the adoption of advanced technologies guide its strategy, with the aim of reducing environmental risks and optimising processes.

- CUSTOMEROperator in industrial and civil liquid waste management

- INDUSTRYWater treatment / waste management

- SOLUTIONDouble diaphragm pneumatic pump in PP

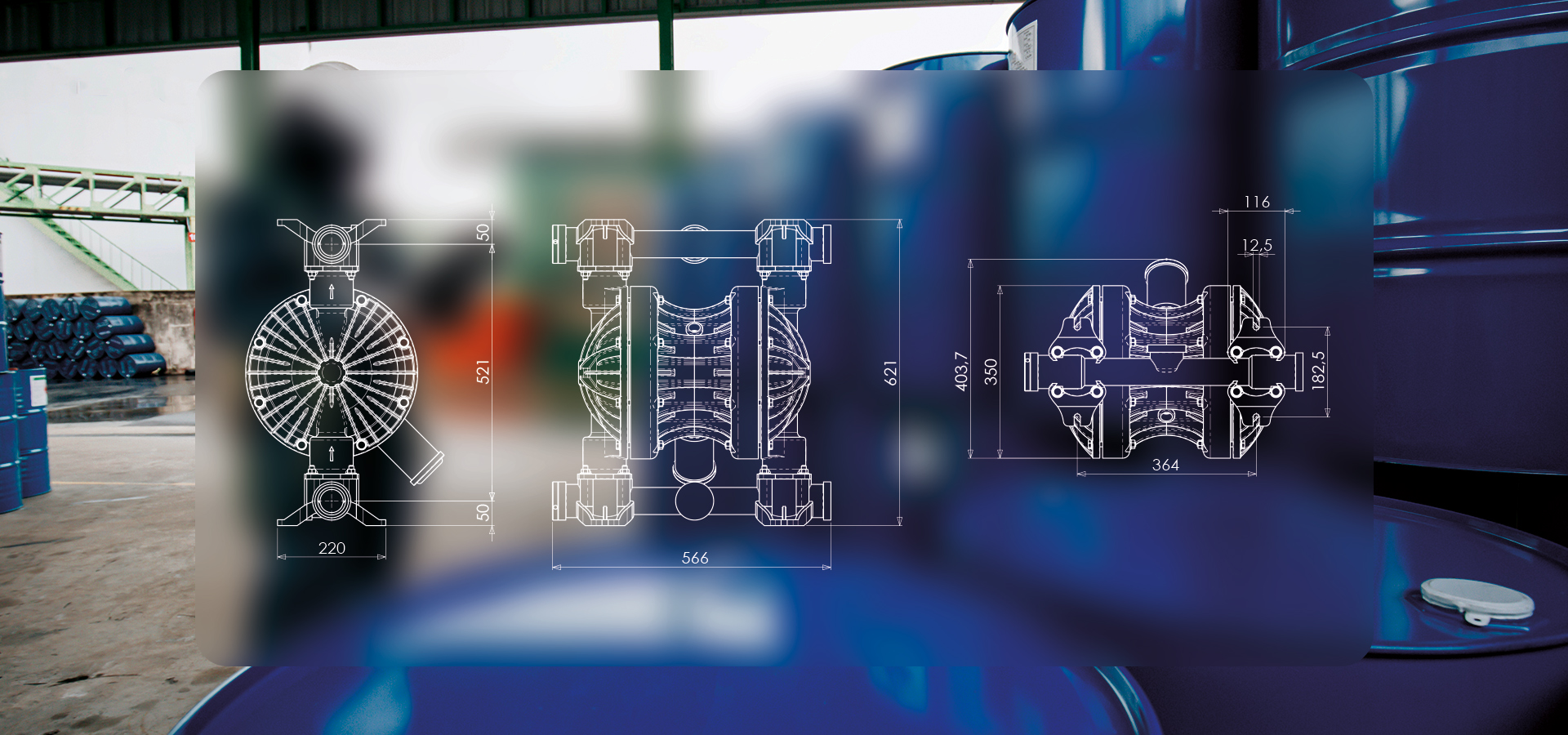

- MODELBOXER 522

Application of BOXER 522: a pump for liquid waste

The Boxer 522 was installed as a liquid waste pump for transferring corrosive and abrasive fluids from collection tanks to treatment systems. The application involves various operating modes, including:

- Suction from mobile and fixed tanks containing industrial wastewater, chemical sludge and liquids with suspended solids

- Transfer to treatment plants or temporary storage containers

- Operation in environments with corrosive vapours, dust or intermittent flow rates

The pump ensures continuity, safety and consistent performance even with non-homogeneous or extremely aggressive fluids.

Operational use of pumps for liquid discharge

The Boxer 522 operates in 8-hour daily shifts, managing multiple transfer cycles from tanks and mobile drums. Thanks to its reinforced PP construction and ability to run dry, it offers concrete operational advantages:

- Stable and uninterrupted transfers

- Reduction of accidental leaks and spills

- Reduced maintenance times thanks to its simple construction

- Wide compatibility with aggressive and viscous fluids

Liquid waste pump: why choose BOXER 522

The company needed a reliable and safe solution for liquid waste management. The main operational requirements were:

- Handling aggressive and abrasive fluids without risk of damage to the pump

- Ensuring staff safety by eliminating rotating parts or electrical components in contact with the fluid

- Reducing plant downtime and routine maintenance costs

Results achieved with Boxer 522

The introduction of the Boxer 522 has led to measurable benefits in the liquid waste management process, including:

- Increased reliability of transfer cycles

- 35% reduction in plant downtime compared to the previous system

- Improved operational safety thanks to pneumatic operation

- Faster transfer processes, even in the presence of abrasives or viscosity variations

- Reduced maintenance, with membrane life exceeding expectations