Electric centrifugal pumps

MB 100

- Max flow rate: 9 m3/h

- Suction connections: G 1″1/2 f o DN 40

- Delivery connections: G 1″ m o DN 25

AUTOMOTIVE

WATER TREATMENT INDUSTRY

CHEMICAL INDUSTRY

GALVANIC AND ELECTRONIC INDUSTRY

DATA

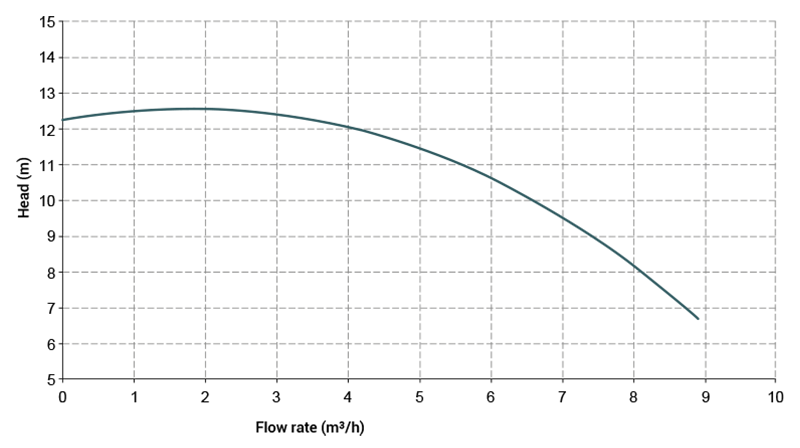

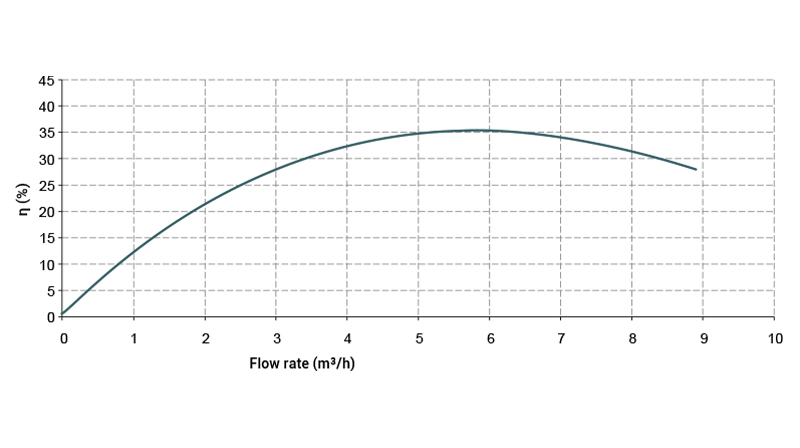

Performance

* The performance values refer to primed pumps (with water at 20°C) with open outlet and vary based on the construction materials.

** Attention: average values of the different materials configurations for ball and ball seat.

DATA

Technical Specifications

Technical Specifications

| Suction connections | G 1″1/2 f o DN 40 |

| Delivery connections | G 1″ m o DN 25 |

| Max flow rate * | 9 m3/h |

| Max head * | 10,5 m |

| Viscosity | up to 500 cps |

| Standard open impeller | Ø 97 mm H 12 mm (special versions are available on request for the fluid pumped) |

| Passing solids | Ø max 7 mm |

Construction materials (casing and manifolds), net weight and temperature

| Version | Weight | Min | Max |

| PP (with glass additive) | 1,7 kg | 0° C | 70° C |

| PVDF (with carbon additive) | 2,2 kg | -10° C | 100° C |

Standard electric motors

- Kw 0,55 – HP 0,75

- Box B3+B14

- RPM 2900

- Aluminium / cast iron motor (the motor weight may vary, contact the sales office)

- THREEPHASE 230/400 V – 50/60 Hz – 2 pole – Efficiency class IE1 – Protection rating IP55 – Ambient temperature -30°C + 45°C

PP PVDF

Electric motors available on request

– SINGLEPHASE

– ATEX

– EPDM

– VITON®

- Protective case in polyurethane foam contained in a wooden case – 50 x 25 x 35 cm – weight 7 kg

The weight refers only to the packaging without the pump inside

- FLANGE KIT (DIN standard – ANSI available on request):

– KITFLANGMB100P (PP pump)

– KITFLANGMB100F (PVDF pump) - PP basket filter o PVD

- Bellows mechanical seal (new generation with “Self-locking” system)

Spring Aisi 304 – Sealing ring in SILICON CARBIDE + CERAMIC / SILICON CARBIDE + SILICON CARBIDE - Lip seal: VITON or EPDM

CONTACT

Ask for more information

TECHNICAL SHEETS