The show has always been a hub for commercial meetings and technological innovation, where industry experts present their latest in engineering and where new services are proposed.

Especially over the last few decades, focus has been placed on the effectiveness of the production cycle and research into new materials, due largely to the increasingly stricter regulations in force.

Especially over the last few decades, focus has been placed on the effectiveness of the production cycle and research into new materials, due largely to the increasingly stricter regulations in force.

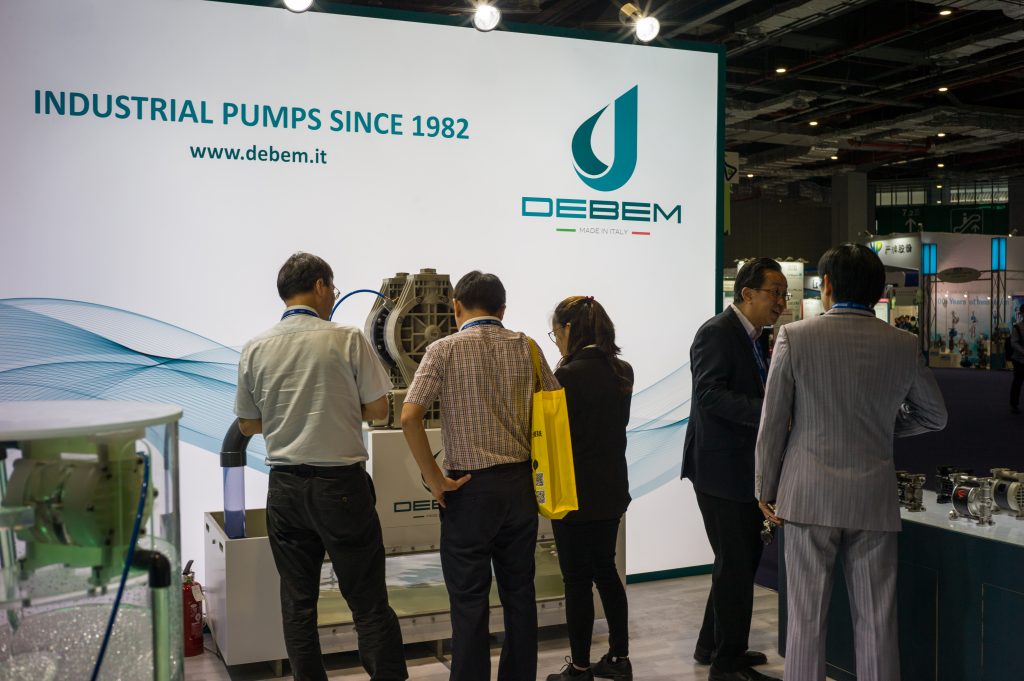

As part of this sphere for innovation and discovery, the AchemAsia fair was held in Shanghai from 21-23 May 2019.

The macro-topics covered included digitalisation, pharmaceutical technology, and safety and technology for water processing and treatment.

We were there with our products to present our latest solutions in the field of fluid pumping.

We were pleased to show the vast number of visitors some of our many pneumatic and centrifugal industrial pumps for treating corrosive and aggressive fluids, technologically advanced products stemming from more than 35 years in the business.

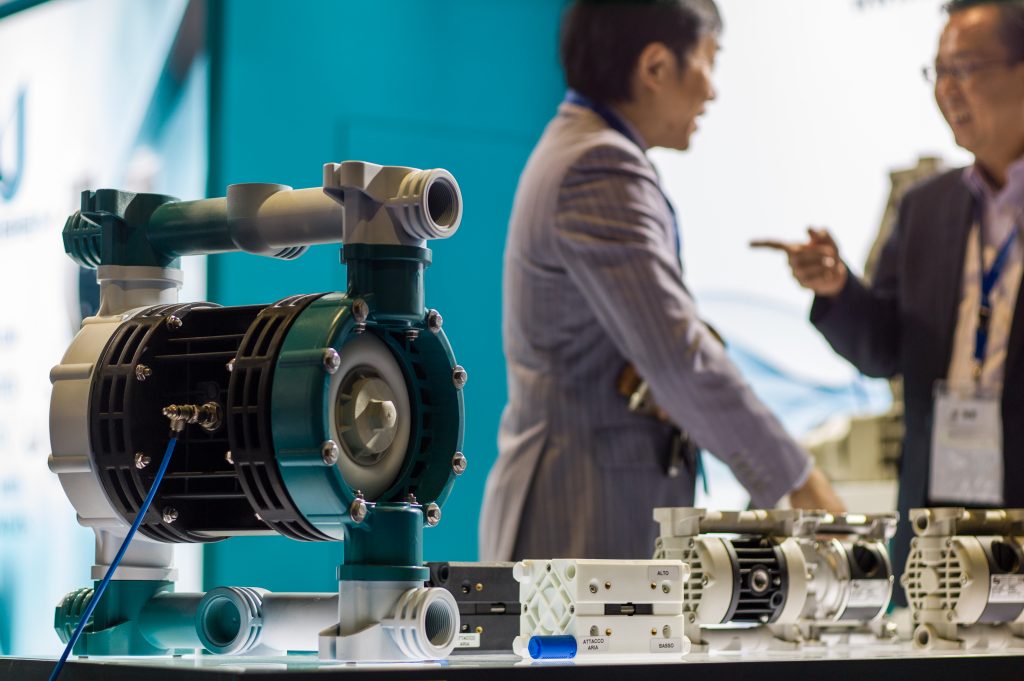

One of the strong points – in terms of efficiency and practicality – of our production is the patented stall-prevention coaxial pneumatic exchanger found in all our Debem AODD pumps.

One of the strong points – in terms of efficiency and practicality – of our production is the patented stall-prevention coaxial pneumatic exchanger found in all our Debem AODD pumps.

This device introduces compressed air to change the equilibrium of the pressure of the diaphragms, assisted by a stall-prevention circuit, that guarantees optimal performance, even in the most critical conditions. Our long lasting stall-prevention exchanger with an estimated 50.000.000 cycles is easy to install, fitted with a self-lubricating system, with no metallic parts, normally subject to chemical aggression, only plastic components.

If you wish to take a closer look at the pump models on display, please follow the links below to the product specification cards:

2020 will also see us taking part in some interesting industry trade fairs, so stay tuned on our Social networks and on our Blog to discover where you can find us!